A device designed to prevent airborne germs and odours from entering the personal space of every passenger in an aircraft has received approval from the FAA for fitment on the A320 family of narrowbody aircraft. The device, named AirShield, was first revealed by its designer, Teague, in 2020, a year when the Covid-19 pandemic was piquing interest in cabin air cleanliness.

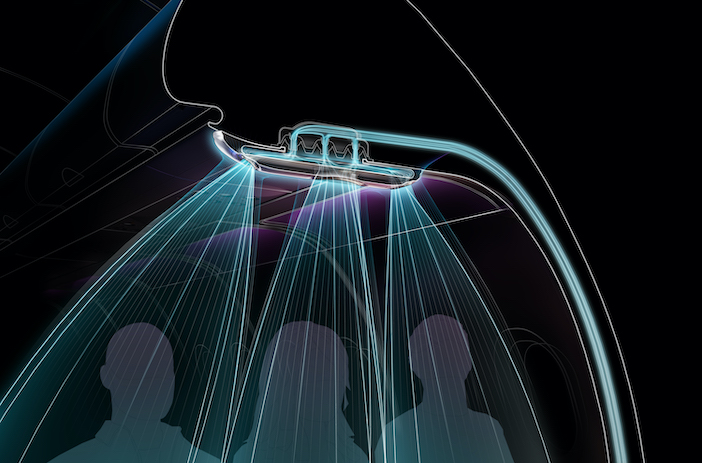

The AirShield device can be clipped in over the existing air vents above every passenger seat, and once in place it works in harmony with the aircraft’s existing HEPA filtration systems to create a directed channel of air that serves as a barrier of germs and odours between and around every seat in the cabin – in effect a ‘virtual distance’ between passengers in high-density cabins where physical distance is not an option.

The design team say that droplets from every passenger’s breath, sneeze or cough are captured and contained by the AirShield, and then sent down to the aircraft HEPA filters before any associated bacteria and viruses can be passed on to other passengers or flight crew. Covid may be less of a concern in the public’s mind nowadays, but clean cabin air will always be a selling point for airlines.

While the AirShield reshapes air flow in the cabin, it does not alter the cabin’s temperature or the volume of air supplied, and the air is not blown directly onto passengers’ faces or bodies, but instead around them to create the air barrier. The technology is claimed to be 50% quieter than standard aircraft air filters.

From theory to production ready

In May 2022 Pexco Aerospace acquired the manufacturing rights to develop Teague’s AirShield from the concept stage to a production-ready design, and anticipated that the unit would be certified by the FAA by July 2022. The FAA’s supplemental type certificate (STC) comes 12 months later than anticipated, but it is now official, and Pexco also enjoyed a little excitement along the way whenAirShield was a finalist in the Health and Safety category of the 2022 Crystal Cabin Awards.

Pexco claims that AirShield reduces the amount of air shared air between passengers by at least 76%, based on tests conducted in an A320 aircraft cabin with every seat occupied and with no passengers wearing face masks. The company also claims that AirShield increases the speed at which contaminated particles are expelled from the cabin and replaced by freshly purified air – indeed Pexco claims the process is some 230% faster than in the same cabin environment without AirShield.

The AirShield unit weighs less than a pound (0.45kg) and is simple to manufacture and quick to install. The three-piece clip-together assembly enables each unit to be installed in less than a minute, meaning an entire aircraft can be fitted with Airshields during standard overnight aircraft maintenance. The Airshield can also be removed in less than a minute, with no remodifications needed to the aircraft to return it to its original state – ideal for airlines that lease aircraft.

As part of the FAA certification process, Pexco had to demonstrate that AirShield is durable enough to withstand abuse and manual interference, while also having a slim form factor that would not obstruct passengers’ line of sight of emergency signage and lighting in the cabin. The company also had to show that AirShield does not impede the smoke evacuation of the existing A320 HEPA filtration system. One relief for the development team was that, as the AirShield units are not located in the ‘head strike’ zone, there is no need for airlines to recertify their seats if they fit Airshields.

The AirShield research programme

According to Pexco, since the inception of AirShield, it has invested more than 8,000 subject matter expert person-hours into the design, generated more than 60 million data points of CFD regarding cabin airflow, and created more than 30 prototypes for more than 100 lab tests. The company also completed 22 on-wing tests in Boeing 737 and Airbus A320 aircraft in collaboration with American Airlines, Southwest Airlines and Alaska Airlines, plus aircraft lessor, Avolon. to ensure the efficacy of AirShield in narrowbody cabins.

Pexco says it found that the HEPA filtration systems in modern aircraft are highly efficient at exchanging and cleaning cabin air in considerable volumes, with the filters removing bacteria and viruses as the air passes through. This was already generally known.

However, Pexco’s research also found that the existing airflow in narrowbody aircraft will inadvertently pull airborne particles and odours across neighbouring passengers’ seats before exiting through the HEPA filters. The company found that having AirShield units in place prevents this cross-contamination from happening.

Jon Page, president of Pexco Aerospace, explains the development process in THIS ARTICLE.

The company also applies an antimicrobial additive during the manufacturing process of AirShield, claimed to destroys 99.99% of bacteria (even antibiotic resistant strains such as MRSA, VRE and CRE) upon contact.

The next step

Pexco is currently in discussions with airlines across the US, Europe and Asia, with the aim of having AirShield installed on A320 aircraft in 2023. Pexco is also exploring certification options for AirShield on other narrowbody aircraft types, including the B737, as well as having the device approved as a line-fit option.

Anthony Ciringione, VP of sales & marketing at Pexco Aerospace, commented: “In the last 20 years the global airline industry has faced SARS, Swine Flu, MERS, as well as Covid-19 and influenza. If history teaches us anything, there will be another airborne pandemic or epidemic – it is only a matter of time. We need a fresh approach to passenger wellbeing in the cabin, implementing long-lasting and proven innovations that improve and hygiene onboard today, so it is effectively prepared for what will come tomorrow.”