The pandemic has forced the airline industry to focus on new ways to improve passenger wellbeing in the cabin. We were dealing with an invisible enemy that moved in unexpected ways and left many passengers feeling uneasy about flying. As a result, hygiene and privacy are now as crucial to the onboard experience as comfort and safety.

With more airlines using narrowbody aircraft, in which passengers sit closer to each other in the cabin, the industry needs to adjust quickly. The next generation of cabin interior innovations will be centred around enhanced passenger wellbeing – and AirShield is a new type of aircraft interior technology, one fit for the post-Covid world.

Back in 2020, there were lots of exciting Covid-safe cabin concepts being unveiled. Few seemed possible to implement without significant changes to aircraft certification. And even then, no one could say whether they would solve the problem effectively.

In the early days of the pandemic, it was thought that surface transmission was a big issue. Only later did the scientific evidence point toward airborne transmission as the primary threat – something even more critical for enclosed spaces such as aircraft cabins.

An idea with impact

The big thing we had to consider with AirShield was how airborne particles behave in a cabin full of people. We started by modelling the cabin airflow in CFD (computational fluid dynamics) to see what was happening to airflow on a particulate level.

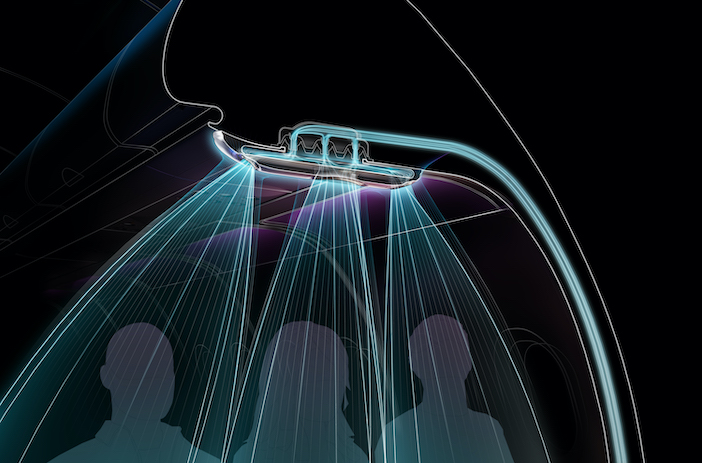

The results found aircraft cabins to be highly efficient at exchanging and cleaning the air in considerable volumes – more so than any other transport environment. But our research also discovered that we could enhance performance by adapting the airflow around passengers’ heads using the existing vents. We can restrict particles and unwanted odours from passing into passengers’ personal space, while speeding up how quickly these particles are sent down to the HEPA filters and replaced by purified air.

After our initial CFD analysis, we prototyped more than 20 different versions of AirShield using 3D printing. These rapid iterations empowered our engineering team to constantly refine the performance of the technology and ensured we could achieve the desired impact without modification to the existing airflow system or any recertification to the seating – an essential consideration for airlines and regulators.

Engineering expertise

Having a novel idea is not always enough. Making a concept viable and bringing it to market is a huge undertaking. During this process, how a product is built and manufactured is equally, if not more important, than the idea itself, especially for airlines requiring hundreds of thousands of units to be installed across a fleet.

Deploying almost 50 years of experience in aerospace engineering and manufacturing, we spent two years fine-tuning the design and performance of AirShield. The result is a unique three-piece assembly that is lightweight (it weighs less than a pound), durable, quick and straightforward to install, and certification-ready.

AirShield devices can be installed as part of routine overnight aircraft maintenance. The unit is manufactured from an antimicrobial material that destroys 99.99% of bacteria on contact (even antibiotic-resistant strains such as MRSA, VRE, and CRE).

To get to this stage, our engineering team needed to complete effective testing procedures to evaluate the efficacy and performance enhancements AirShield could bring to the cabin, including cabin airflow, Db level, G-Force, and flammability testing. These tests have been crucial in helping take AirShield from just another concept to a state-of-the-art air management technology capable of protecting passengers and elevating the inflight experience.

The challenge of certification

Certification is probably the biggest hurdle to bringing blue-sky innovation to the cabin. While the process plays a crucial role in ensuring the efficacy of innovations and that every part of the cabin interior is safe and functioning correctly, it can also be costly and time-consuming. You need experienced engineers to manage every step of the testing process and work with regulators like the Federal Aviation Administration (FAA) and its Designated Engineering Representatives (DERs).

With AirShield, securing the collaboration of airlines and aircraft lessors was vital as it enabled us to complete on-wing tests in real aircraft. In the early development phase, we conducted extensive on-wing tests aboard A320s in partnership with some of the world’s pioneering airlines, including American Airlines, Southwest Airlines, and Alaska Airlines. We also partnered with Avolon to perform on-wing tests; without Avolon’s assistance, the testing would have been delayed for several months, as finding an aircraft for on-wing tests during the busy summer months is very difficult. The data gathered during this process informed the engineering development of AirShield. The data helped us maximise the potential of the design and proved its ability to enhance passenger wellbeing in the cabin.

Since the idea’s inception, we have invested more than 8,000 subject matter expert person-hours, generated more than 60 million data points of CFD, engineered more than 30 prototypes for more than 100 lab tests, and completed 22 on-wing tests in the aircraft of four major airlines. It has been a long road to certification, but AirShield has received PSCP authorisation from the FAA (approving all the test parameters), with final STC certification expected shortly.

Building momentum

The aircraft interior industry is a competitive market. Even with a certified innovation, you need momentum, awareness and demand in order to provide the best platform for airlines to adopt your idea.

To help us build that momentum for AirShield, we, together with Teague, invested in an independent passenger survey of US leisure travellers. The results were more conclusive than we could have imagined:

• 91% agreed that AirShield makes them feel like an airline is taking care of them

• 89% would feel more comfortable flying with AirShield post-pandemic

• 86% of respondents stated they would choose to fly with an airline with AirShield installed over one without

• 71% were also willing to pay more to fly on an airline that equips its planes with AirShield

Knowing what we know now about airborne viruses, we expect these numbers to be even higher if we were to do the survey again today.

We also created a full-size A320 mock-up and VR system, which we debuted at Aircraft Interiors Expo 2022. We did this so the whole industry could see how AirShield worked in practice and understand the rigorous data and engineering behind the product in the run-up to it being ready to install on A320s in early 2023.

Time to take off

Since the pandemic’s peak, flight schedules have bounced back, and things would appear to be back to normal, but they are not. The pandemic has fundamentally changed the way that people feel about public spaces. Even though passengers are no longer required to wear face masks onboard every flight, there is still a strong desire for an additional level of personal protection – especially in economy class, where there are no physical barriers such as screen dividers or suite doors.

In the absence of the visual safety cues in the cabin that we saw throughout the pandemic (like face masks and empty middle seats), the industry must now deliver effective, visible, and lasting changes that respond to the needs of post-pandemic travellers.