Safran’s impressive stand at Aircraft Interiors Expo 2019 showcased a number of new products, chief among which was a modernized galley. Other new technologies included an AI-powered surveillance system, an new type of cabin lighting, and a manual espresso machine. The company also announced a deal with Corsair and Avolon to outfit three new A330neos.

Modernized galley kitchen

The major attraction on Safran’s stand is a split-design galley, to show the difference between, on the one hand, the standard, non-connected and very industrial-looking galleys as are common on aircraft today, and on the other hand, Safran’s modernized version, which will be available at the end of next year.

The galley features a contemporary design, with easy to understand illuminated switches, black paneling and angular styling. More importantly, however, the switches are customizable and the company is working on a connected ‘IoT’ version.

The IoT version features a fold-out tablet that connects to other aircraft systems, such as the IFEC. This might in future allow it, for instance, to start heating up food autonomously when a passenger orders something on the IFE, or to aid predictive maintenance.

Another visual upgrade is the elimination of visible door catches for the modules. Instead, the hinges and internal mechanism are designed take all the force required to keep the door shut.

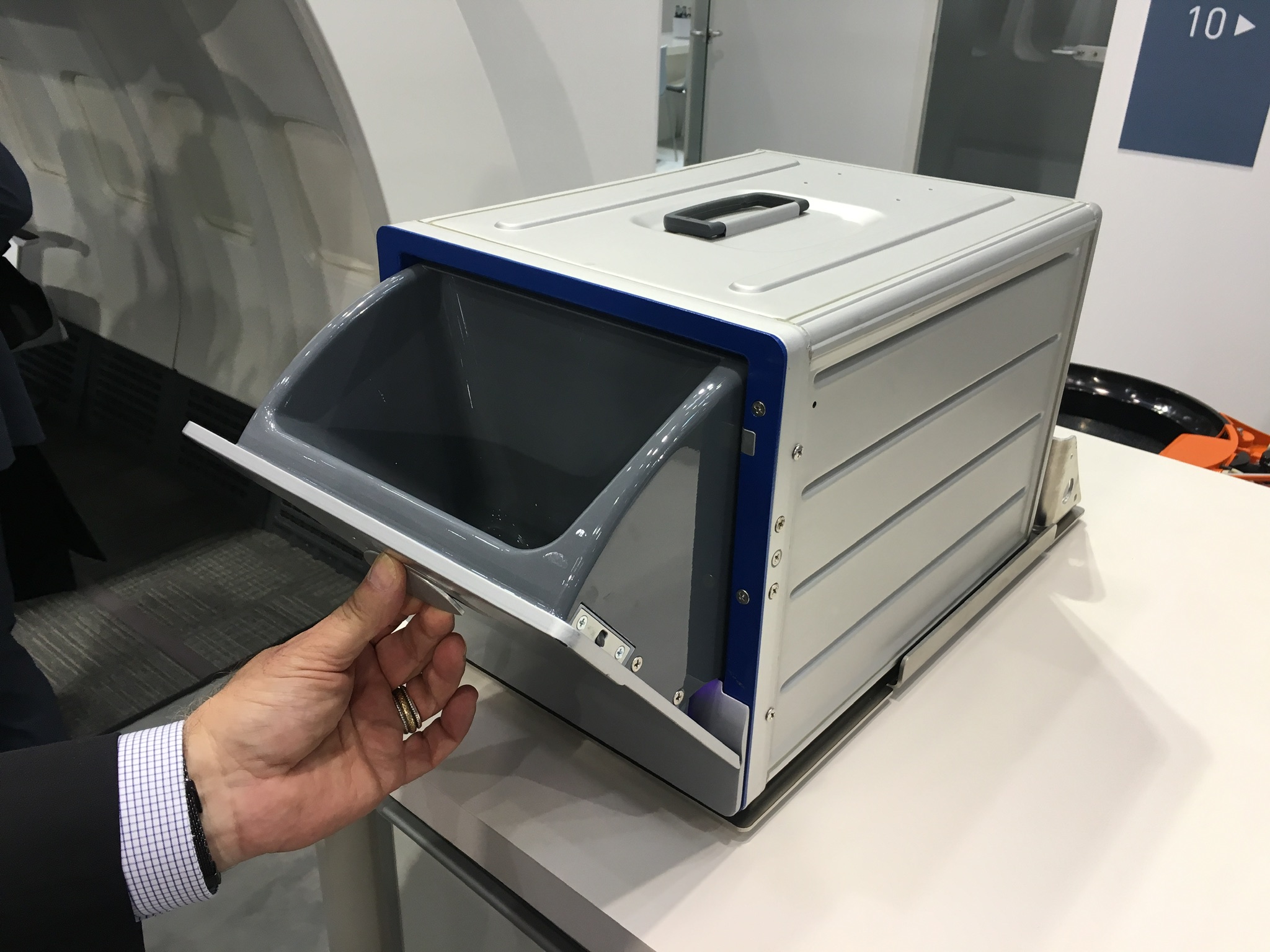

As part of the modernized galley, Safran also presented a cooled compartment which doesn’t require a separate chiller. Especially for short-haul flights, the noise and weight of the chiller is not desirable. Safran says that the new compartment, at around 11kg, is approximately half the weight of a regular chiller. It is also completely silent and the temperature can be controlled through the integrated tablet.

The chilled compartment also features electroluminescent paint, which lights up by itself without using any power. This paint can be used in all compartments that need some illumination, but don’t require bright lights.

AI surveillance system

A new system to count passengers and to recognize situations that need attention also featured on Safran’s stand. Named Aisee, it uses artificial intelligence to spot behavior that is suspicious, such as aggressiveness, people lying down in the aisles, or if an obstacle is blocking an emergency exit door. It can then automatically alert cabin crew.

This system is a development of a system Safran designed for Airbus four years ago. It has now enhanced the system with artificial intelligence and deep learning functionality.

Safran to supply technology for Corsair Airbus A330neos

Safran also announced that it has an agreement with Corsair and Avolon to supply its latest interior solutions for the three new Airbus A330neos that Corsair has on lease from Avolon.

Safran will supply a full suite including Z400 tourist-class seats, combined with the lightweight RAVE IFE system, embedded with amenities such as personal displays and power outlets at every seat. The company will also deliver lower deck crew rests and modern galleys.

“We look forward to launching our new service for our passengers with a modern, efficient and comfortable cabin from Safran”, said Pascal de Izaguirre, CEO of Corsair. The airline will take delivery of the first of three A330-900 aircraft from Avolon in late 2020. Corsair is standardizing on the A330 in order to be able to offer consistent and excellent service to meet the expectations of their over 1.2 million customers.”

Safran Seats CEO, Vincent Mascré said, “Safran Seats is honored to provide Corsair our Z400, a lightweight seat with industry-leading comfort for tourist class passengers. In addition, the best in class Z535 premium economy seat meets the Corsair customer expectation of a well-appointed cabin.”

Manual espresso machine

On a less serious note, Safran also developed a manual, lever-operated espresso machine. It requires no power, allowing it to be mounted on a cart and pushed down the aisle. The thermally insulated reservoir is filled with hot water, after which a standard coffee pad is placed in the machine. A manual lever is then pressed down – replacing the pump that normally powers commercial espresso machines – to extract the coffee.

On a less serious note, Safran also developed a manual, lever-operated espresso machine. It requires no power, allowing it to be mounted on a cart and pushed down the aisle. The thermally insulated reservoir is filled with hot water, after which a standard coffee pad is placed in the machine. A manual lever is then pressed down – replacing the pump that normally powers commercial espresso machines – to extract the coffee.

While the machine requires some crew training, it is simple enough to operate, and as there are no water pump or boiler to require energy, it can be used on the move. We tried the result on the stand and can attest that the resulting coffee is very good, not to mention spectacularly better than the instant coffee often served on airplanes.