Seattle-based design company, Teague, has developed cabin hardware conceived to help minimise the spread of germs in the aircraft cabin. Named AirShield, the concept is a germ isolation system that controls cabin airflow to restrict the spread of viruses.

Existing research suggests there are two known transmission processes for the coronavirus that causes Covid-19: either as an airborne particulate or from viral particles which have settled on surfaces.

While most airlines have introduced stringent aircraft cabin sanitation and cleaning processes before boarding to minimise the risk of surface transmission of coronaviruses, those procedures do not address the spread created through close contact from person to person (through respiratory droplets that land in each other’s mouths).

Although airlines are mandating the use of face masks, the use of these on-board is limited to passenger adherence, which will fluctuate due to physical discomfort and the need to eat and drink. Therefore, the ability to control sanitisation diminishes rapidly when the cabin is populated, found Teague’s design team.

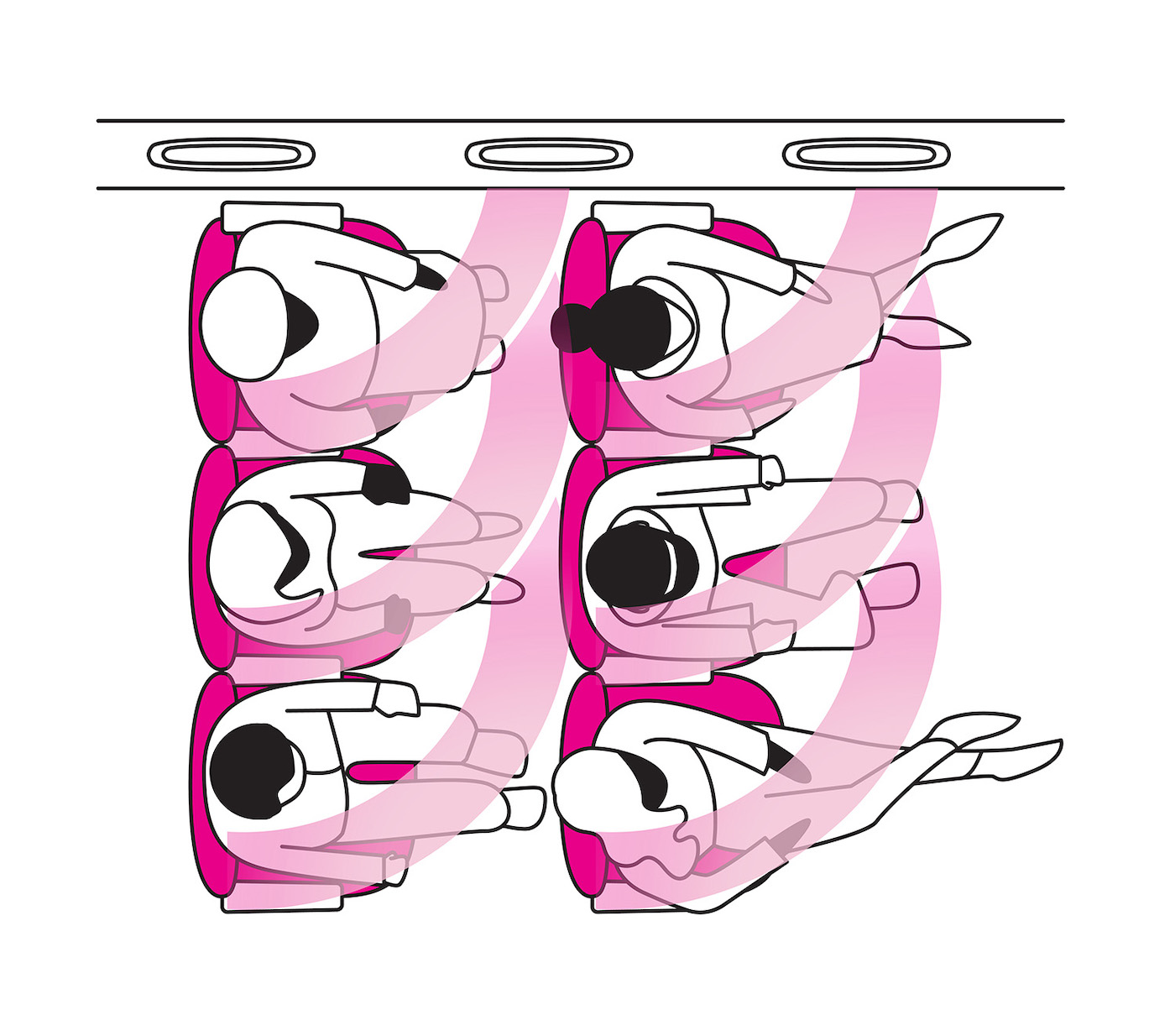

Passengers behaviour in unpredictable, so the AirShield is a measure provisioned by the airline. The shield is a single 3D-printed component that fits directly onto the passenger service unit (PSU) positioned above every passenger in the cabin. Airflow from the existing overhead air-gaspers is channelled through the AirShield, transforming freshly purified air into engineered ‘air-blades’ capable of controlling the spread of droplets much more effectively.

As a result, when a passenger breathes, coughs, or sneezes, the water vapour droplets are contained within that passenger’s personal space and immediately re-directed downwards and out of the cabin to the HEPA filtration units, before they have the opportunity to enter the personal space of a neighbouring passenger.

The research process

Aircraft are one of the safest modes of transport, even during today’s Covid-19 threat, with HEPA air filters ensuring the quality and sanitation levels of recycled air remain incredibly high. However, Teague found that airflow on-board an aircraft is largely vertical, with air dispersed at the top of the cabin and along the sidewalls. The air is then pulled out of the cabin through ducts in the floor, filtered and refreshed every few minutes. This process can extend the trajectory of an infectious water vapour droplet past multiple passengers before it is decontaminated – potentially resulting in one person infecting several others.

To better understand how germs travel in the aircraft cabin, Teague initiated a series of computational fluid dynamics (CFD) simulations to evaluate various aspects of particulate movement in the cabin environment. The initial results demonstrate the potential to re-direct the spread of exhaled respiratory particles from passengers.

“In an aircraft environment, it is airflow and not the distance that plays the most significant role in the spread of a virus. By engineering the cabin airflow to manage each individual’s exhalations, passengers can have far greater peace of mind when seated nearby,” said Anthony Harcup, senior director of airline experience at Teague, who co-invented AirShield.

“For many airlines, it is simply not commercially viable to reconfigure entire cabins to adhere to social distancing measures – especially in economy class, where passenger density is at its highest. A reconfigured interior would also not guarantee passengers the same level of protection from infectious droplets travelling through the cabin when compared to AirShield,” he added.

“Coronavirus and the use of masks will go away long-term; however, the world’s expectations for elevated hygiene post-pandemic will remain. The enhanced interpersonal protection that Air-shield is set to deliver will be a valuable tool for the industry in the quest for a cleaner, safer cabin.”

The AirShield concept is now entering its engineering development phase in anticipation of rapid deployment to help restore confidence in air travel.