S7 Technics has launched an automated plant in Russia for the production of Airbus cabin floor and interior panels. The 42 square meter production area, at S7 Technics’ base in Mineralnye Vody, will be able to produce 10-20 panels per working shift.

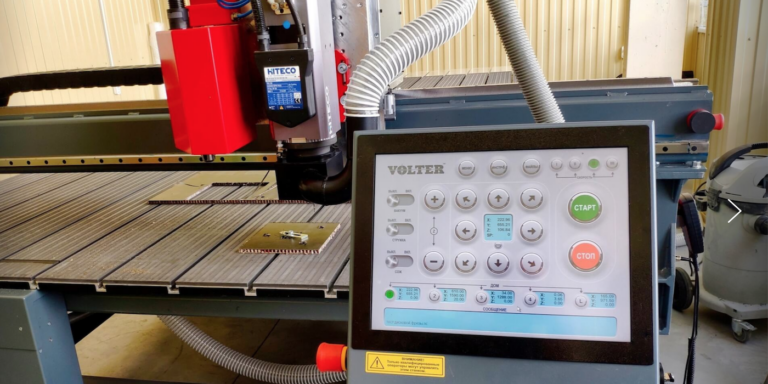

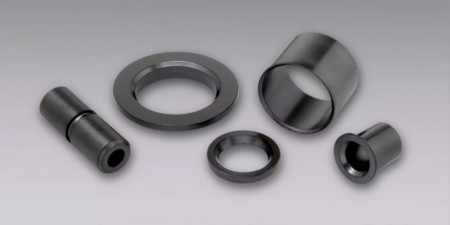

The panels will be manufactured from composite materials by milling on a high-precision computer numerical control (CNC) machine made by Volter, a Czech company. The process begins with graphic processing (creating a 3D model of panels, and then preparing programs for the CNC machines) and ends with a certificate release for the finished products. The work is performed by experienced S7 Technics specialists who have already completed training courses in working with CNC equipment and programming.

The new manufacturing process includes the automation of part of S7 Technics’ structural repairs department. Previously, the panels were made by specialists in the aircraft structural repair shop, using hand tools. The automated process enables S7 Technics to reduce the financial and time costs of panel production. According to the company, the purchase of ready-made panels from OEM companies is 20-30% more expensive than those made using S7’s automated process, and also takes longer to be delivered.

“During base maintenance checks such as C-Check, 30-80% of the aircraft cabin panels are replaced. According to redelivery check – from 60% to 90%. Our own production of panels will speed up the process of replacing them on aircraft that are undergoing maintenance, thereby reducing the TAT (turn-around-time),” said Maxim Akchurin, business development project manager at S7 Technics.

The automated plant also enables the company to produce panels that it could not manufacture previously – the roof panels of the cargo compartment, for example. When S7 processed these panels manually there was a high probability of damage due to their large dimensions, but the updated production site enables such components to be manufactured safely, meeting all technical requirements.

S7 Technics is initially focusing on the production of panels for A320 Family aircraft. However, if the company identifies stable demand in the market for its panels, further modernisation of the production area is possible, to accommodate the manufacturing of panels for Boeing and Sukhoi Superjet 100 aircraft.

The new production unit will operate under EASA Part-145 until the end of 2021, which enables panels to be manufactured at S7 Technics’ base at Mineralnye Vody, as well as its Moscow and Novosibirsk facilities. Next year, a transition to the EASA Part-21 G certificate is planned, which will enable the company to manufacture and sell panels with the issue of the EASA Form 1 certificate.