Etihad Engineering, the MRO division of Etihad Aviation Group, has opened the first additive manufacturing facility in the Middle East region, with Design and Production Approval from the European Aviation Safety Agency (EASA). Etihad Engineering collaborated with two 3D printing technology providers, EOS and BigRep, to create the facility, which will enable the design, production and certification of 3D-printed cabin parts.

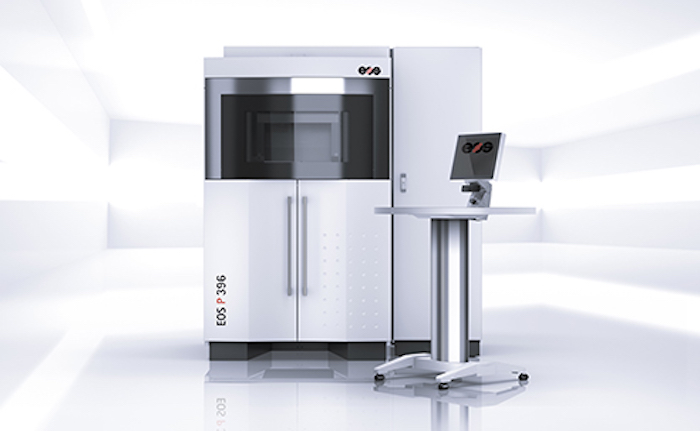

The laboratory, located at Etihad Engineering’s facility adjacent to Abu Dhabi International Airport, features two approved industrial 3D printers. The laboratory’s primary machine is the P 396 powder-bed fusion technology system from EOS, which enables faster production and reduced weight of aircraft cabin parts, compared with traditional manufacturing processes.

Etihad Engineering, together with its partner EOS, received one of the first airline MRO approvals from EASA for 3D printing using powder-bed fusion technology, which the company intends to use to design, produce and certify additively manufactured parts for the aircraft cabins of the future.

Markus Glasser, SVP for export region at EOS said, “Together, we want to bring the design and production of aircraft interior parts to the next level. Producing cabin interior parts additively will offer a substantial value-add in terms of optimised repair, lightweight design, shorter lead times and customisation, addressing some of the key challenges of the aerospace industry.”

The EOS system can produce serial parts from polymer materials such as PA 2241 FR, and enables the manufacture of cabin parts for an aircraft heavy maintenance C-Check. Cabin defects can also be rectified within a short turnaround time, which allows for the production of the required cabin parts during line maintenance.

The EOS machine operates with a total build volume of 340 x 340 x 600mm and enables the tool-free manufacture of serial components, spare parts, functional prototypes and models, directly from CAD data.

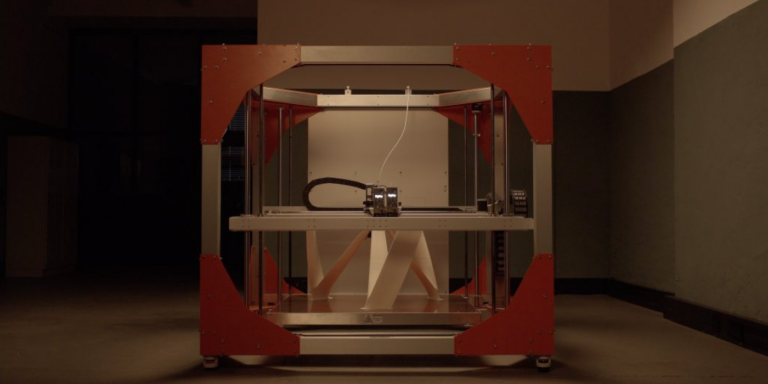

The second machine is the BigRep ONE, one of the largest, serial-built industrial thermoplastic extrusion 3D printers. The ONE is designed for manufacturing large parts, jigs and fixtures as well as moulds, on site and on demand.

“Together with Etihad Engineering, we will develop the full potential of additive manufacturing”, said Martin Back, BigRep’s managing sirector. “In the next phase, a BigRep PRO, the most advanced large-format FFF 3D printer, will be installed.”

Etihad Engineering first received EASA approval to 3D print with filament technology in 2017, when it became the first airline MRO in the world to certify, print and fly 3D printed cabin parts. The latest approval covers the powder bed fusion 3D printing technology.