Following independent testing by Industrial Microbiological Services, Alpine Advanced Materials says that the antimicrobial coating on its HX5 thermoplastic nanocomposite decorative finishes has been proven to be effective. Samples of HX5 coated with Signature Plating’s SignaShield antimicrobial clearcoat showed a 99.93% reduction in Staphylococcus aureus, and a 99.92% reduction in E. coli, according to the company. Those coated with copper and SignaShield showed comparable reductions.

“As manufacturers face heightened attention on microbe transmission, materials like HX5 will need to be evaluated through that lens, which is why we had this testing done,” explained Roger Raley, president of Alpine Advanced Materials. “Part of what makes it great is how well it handles, not just during the manufacturing process, but also when coated or plated. We learned that it not only coated beautifully with SignaShield, but that it also virtually eliminated all harmful microbes when exposed, making it ideal for parts with surfaces that get a lot of contact traffic.”

Signature Plating’s SignaShield has been tested, passed, and certified to ISO 22196:2011 to show it reduces microbes on part surfaces, preventing the spread of bacteria. Alpine Advanced Materials says that the coated HX5 was also tested and certified to ISO 22196:2011 and that surfaces coated with SignaShield have been proven to reduce microbial loads and the potential for cross-contamination, with the antimicrobial protection lasting for the lifetime of the coated part.

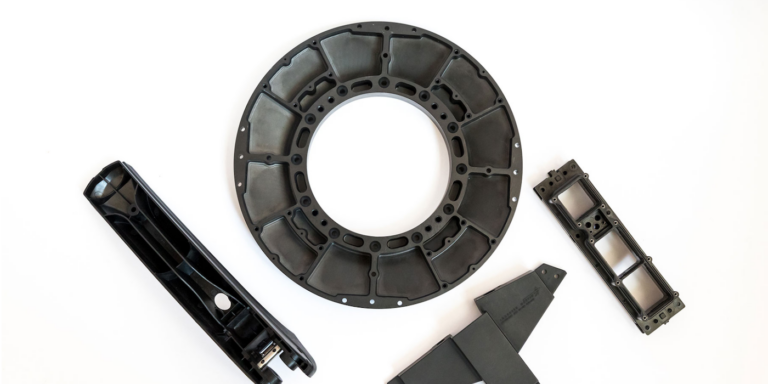

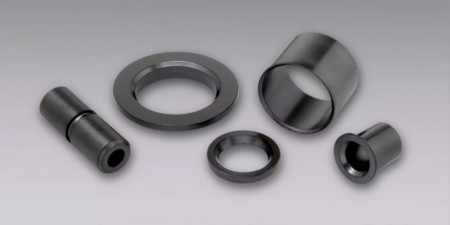

HX5 is a lightweight aviation-grade thermoplastic nanocomposite, engineered to replace machined aerospace-grade aluminium, but at half the weight, according to Alpine. The material was developed over more than a decade of testing and validation by the US Department of Defense, with an R&D investment in excess of US$50 million. As well as having a high strength-to-weight ratio, HX5 is claimed to offer thermal stability and environmental resistance, as well as manufacturing flexibility, as it can be injection moulded, formed, extruded, or machined like aluminium, allowing component manufacturers to make complex but strong shapes.

Earlier this year, Alpine completed Electromagnetic Interference (EMI) testing on HX5 and found its attenuation properties provided effective EMI shielding. It was also shown in additional third-party testing to retain up to 96% of its original mechanical performance when subjected to 5 million rads of gamma radiation. Alpine says that HX5 has also demonstrated extreme corrosion resistance to solvents, fuels, lubricants, and chemicals.