The behaviour of plastics changes in line with different temperatures and strain rates. Thus when designing plastic components, it is important to know the behaviour of the plastic used, not only under laboratory conditions, but also under the subsequent conditions of use, considering the entire spectrum of possible operating temperatures.

To this end, scientists at the Fraunhofer Institute for Structural Durability and System Reliability LBF in Germany have extended the dynamic possibilities of their modified high-speed testing machine by adding a device that enables plastics to be examined at low temperatures – validated down to -40°C – without a thermal chamber.

This new device enables the Fraunhofer LBF team to investigate plastic properties at temperatures below room temperature, for several sectors including the aerospace industry. In addition, they can measure the strain optically with DIC/GSC (Digital Image Correlation/Greyscale Correlation) and thus determine a 2D strain field on the test specimen, from which the longitudinal and transverse strains are derived.

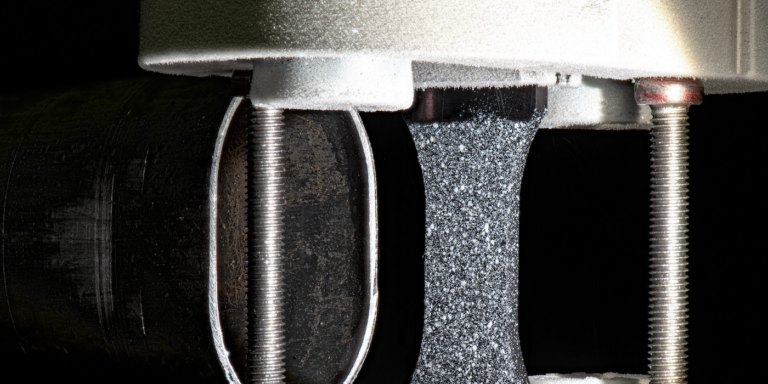

Low temperatures are created using compressed air cooled by liquid nitrogen, with the sample placed in the airflow. A thermal camera monitors the temperature over a large area, and the team starts the measurement as soon as the desired temperature is reached. The advantage of mixing compressed air and nitrogen is that the compressed air is dry and only a few ice crystals form on the sample surface. According to the institute, the gas mixture from the cold reservoir ensures a more constant temperature of the airflow than when nitrogen is applied directly.

From granulate bag to material card, everything in one hand

The cooling device, developed in-house at Fraunhofer LBF, consists of a controller and switching element, a cold reservoir, a nitrogen tank, and a supply line to the sample. There is no thermal chamber, which offers the advantage that there is no pane between the camera and the sample, which could tarnish, freeze or form air vortices when the pane is heated. This not only benefits DIC and thus the results, but also allows flexible testing of different component sizes and different load types. The researchers have successfully put the cooling unit into operation.

Fraunhofer LBF says that the cooling device completes its competencies in the application-relevant temperature range, enabling the institute to implement the entire process, from the delivery of a granulate bag to the validated material card from a single source as the processing and testing conditions are precisely known.

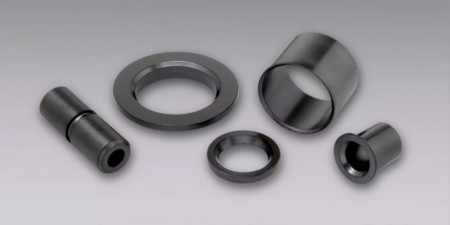

The LBF team prefers to produce plates from the supplied granulate, from which they then mill various test specimens at any angle. Material cards are created from the data obtained. For validation and investigation of morphological influences, a microcomputer tomograph is available to determine fibre orientations.