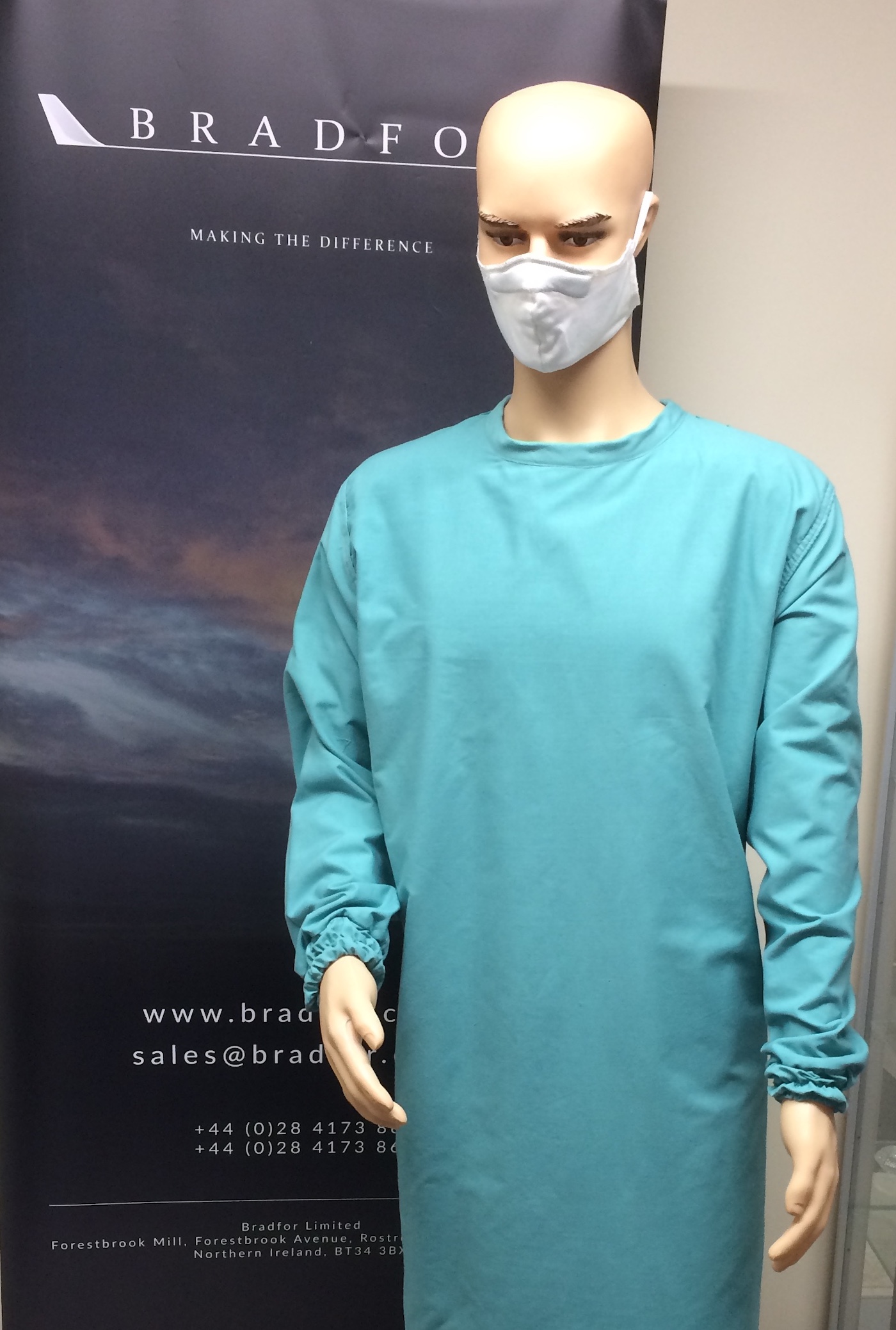

Northern Ireland-based aircraft seat cover manufacturer, Bradfor, has diversified its offering by sewing over 12,000 scrubs and gowns, which have been provided to healthcare organisations across Ireland to help in the fight against Covid-19.

The company closed its factory in mid-March due to the pandemic, but since the beginning of April it has since made substantial changes to its factory so its team can sew PPE equipment for use in many hospitals, health care trusts and local health centres.

Patricia Clements, managing director of Bradfor, commented, “Bradfor Ltd has been operating for nearly 25 years and with a workforce of over 100, which include numerous seamstresses, this was a very obvious step for the company to take. Working in the aerospace sector where quality, excellent lead times and high-quality manufacturing is the norm, we knew where we could add value in this rapidly changing environment.

“We are very lucky in that our factory is over two floors and lends itself to social distancing. We’ve also put a number of extra measures in place, from staggered start times and breaks, to added infrastructure and a one-way system to protect our employees. To date we’ve been fortunate in the number of enquiries regarding manufacturing scrubs and gowns, and our highly trained seamstresses were only too delighted to assist during this pandemic. As a company, I also wanted to be able to help those locally and we’ve just donated some gowns and scrubs to Kilkeel Health Centre and Warrenpoint Health Centre. We are very much rooted in our community and if we can help, we will.”

Known for specialising in dress covers, upholstery fabrics and leather and providing seat covers, headrest covers, straps and diaphragms, along with digitising design services to a range of global clients, Bradfor Ltd has expert knowledge in materials and sewing.

Clements added, “The company has a dedicated team of highly skilled professionals and is keen to continue to assist and make scrubs and gowns. We’re also looking at making face masks, which are undergoing various trials with one of our global customers. We are using a polycotton, breathable and washable material, which seems to work well for many.”