EconCore, Toray Advanced Composites and Bostik have co-created a thermoplastic honeycomb core sandwich panel for use in mass transportation, including aircraft interiors. The three companies collaborated to develop an alternative to the often expensive and labour-intensive fabrication of parts using a conventional sandwich layup – a process commonly used in aerospace – such as the use of phenolic prepreg skins and phenolic impregnated aramid honeycomb core.

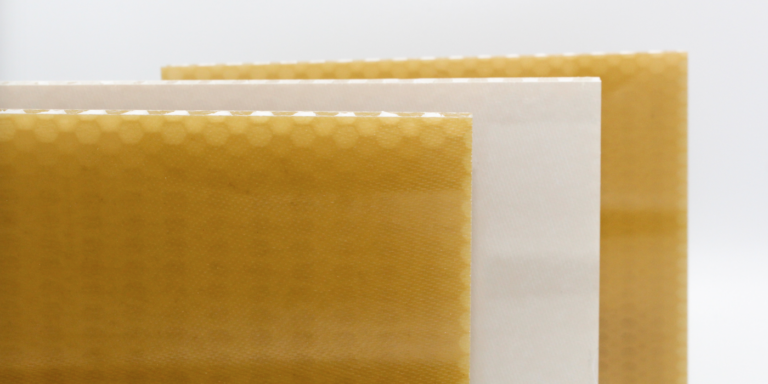

With the new process, Toray’s Cetex reinforced thermoplastic laminates are used as skins for the panel, together with EconCore’s thermoplastic honeycomb core with FST (fire, smoke and toxicity) qualification, and Bostik’s flame-retardant thermoplastics polyester web adhesive. According to the partners, the collaboration has seen the new material pass fire, smoke and toxicity regulations applying to aircraft interiors.

While the thermoset system can require handling and processing of sandwich components into the final part – a process which can take several hours, including the curing process – EconCore says that its continuous process and compression moulding for thermoplastics means that it just takes around 60 seconds to form the desired shape.

When the EconCore thermoplastic honeycomb skin reaches the end of its service life, it can be recycled, shredded and repurposed into composites.

Tomasz Czarnecki, COO of EconCore, stated, “We are excited about this collaboration, especially as we have been able to develop a sustainable technology that is recyclable and which, next to the automotive and transportation applications where it is widely used already, has the potential to be used in a variety of markets such as rail, aviation or ship building.

“With the FST thermoplastic honeycomb technology, we are looking for cost savings at both ends; within the continuously produced honeycomb core and panel, as well as within the fast, easy and clean conversion of a sandwich panel into a lightweight sandwich part.”

Whilst the thermoplastic honeycomb core and skins are often welded to each other within EconCore’s technology, the use of an adhesive from Bostik allowed for the reduction of lamination temperatures and processing simplifications.

The phenolics usually used for curing have been replaced with a web adhesive, which, according to Bostik, is flame-retardant and meets the FST requirements, and represents a new means of application which enables new possibilities to produce lightweight materials.

By using the reinforced thermoplastic composite laminates from Toray as the skin, the material can be easily moulded rather than going through a rigorous process of being covered in phenolics, then setting, followed by being shaped by hand.

Frank ten Napel, segment manager for aircraft interiors at Toray added, “This application demonstrates the versatility of thermoplastic composite technology, and the efficiencies it can bring to processing technologies throughout the value chain.”