Starling Aerospace has been seeing significant growth in demand for bespoke aircraft interior refurbishment projects, from both private and commercial aviation customers. This demand has led the company extend its design and manufacturing capability, with a ‘six figure investment’ in its sewing shop.

The aircraft interiors specialist, located in Leatherhead, Surrey (between London Heathrow and Gatwick Airports), has become the only UK aerospace company to operate a three-in-one combined CNC perforating, stitching and embroidery machine. The company has also upgraded its sewing shop with the installation of six fully automated Juki sewing machines.

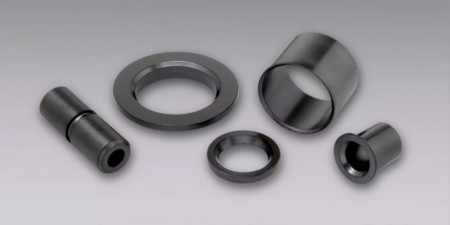

These investments add to the recent commissioning of Starling Aerospace’s first in-house autoclave, which facilitates the fabrication of aircraft cabin interior panels, fixtures and fittings. These components are made from carbon fibre, pre-impregnated with a resin system and curing agent, for high strength, light weight and a high-quality finish.

“This major investment in machinery represents the biggest upgrade in Starling’s capability since the company was established more than two decades ago,” said Coralie Wigg, Starling’s co-founding director. “By combining different sewing tasks into a single CNC machine, we can create any design for leather and fabric, no matter how complex. Equally, our in-house autoclave provides an agile solution for customers needing a fast project turnaround. Starling is seeing a growing trend for completely bespoke interiors, so we are well positioned to deliver the increasingly exotic designs that our clients are demanding.”

As well as design and fabrication, Starling now manages aircraft interior modifications, re-certification and installation, as part of its end-to-end service.