Aircraft interior products supplier, Jamco America, is making its machine shop available for external contract manufacturing and customisation projects for the aerospace industry. The company’s machine shop in Everett, Washington has been operational for nearly 30 years, during which its capabilities have been expanded from basic machining equipment, to extensive, cutting-edge technologies.

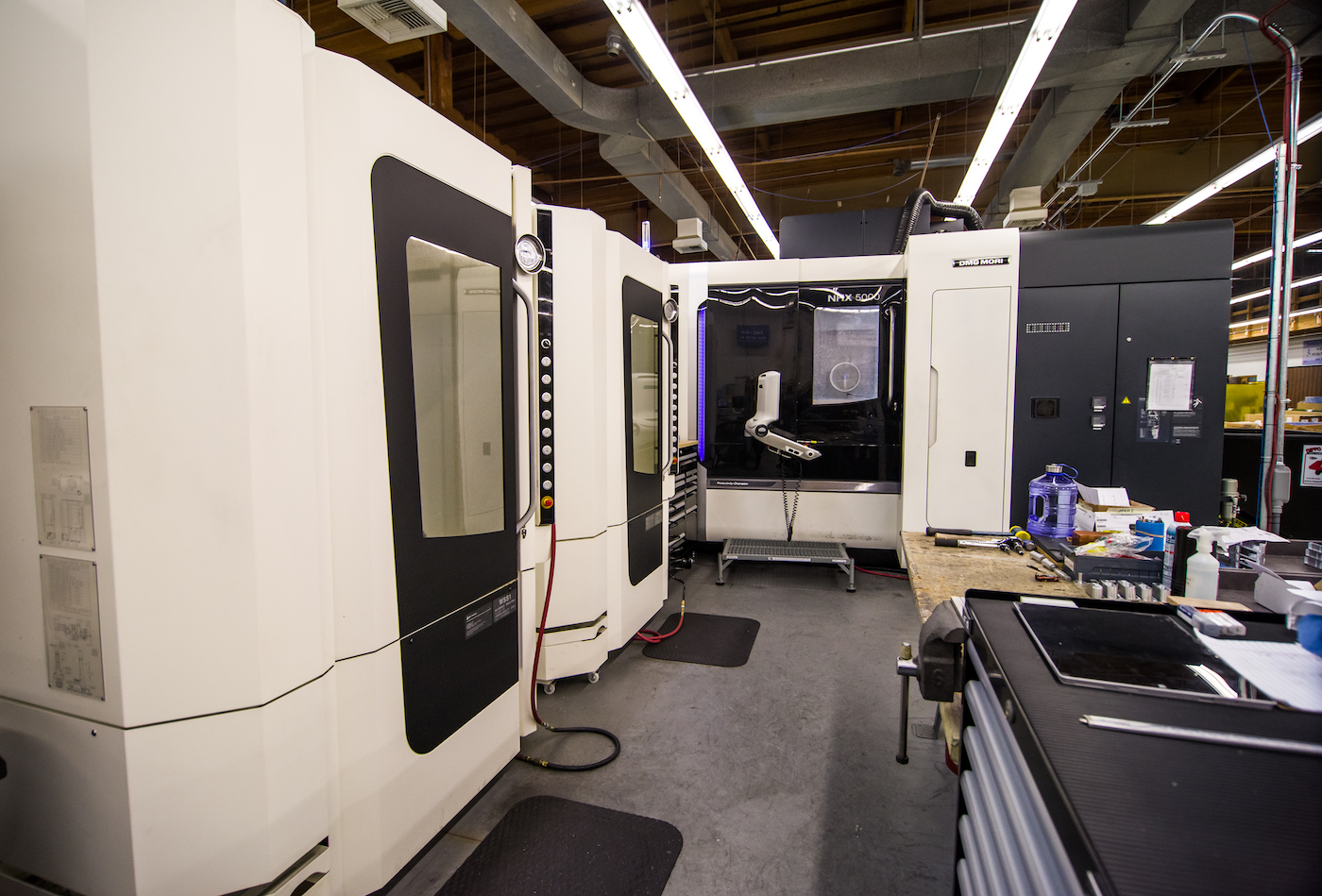

The shop’s capabilities include sheet metal bending, profiling, and forming; countersinking, dimpling, riveting, and other preparations for sub-assembly; large four-axis horizontal milling and machining; smaller three- and four-axis vertical machining; and lathe turning for round components. The large four-axis machine centres hold 240 tools each, and an automated 36 pallet cell for flexible and efficient milling 24/7, to help achieve rapid project turnaround times.

According to Jamco America, one of the shop’s most notable capabilities is its freeform CNC tube bender, installed in summer 2020. This machine is used to form round tubes into tubing frames, and is currently used for tasks such as producing Jamco’s Venture business class seats with embedded aluminium edge trim.

The shop also houses a digital cutter/router for composite materials, open-cell cores, textiles and more. Used traditionally in the sign-making industry, Jamco has adapted this technology for aircraft seating and other cabin interiors projects.