HAECO Cabin Solutions has launched a range of certifiable devices that allow package stowage in the main passenger cabin of aircraft.

As the Covid-19 environment developed, the company noted that airlines were beginning to use passenger flights strictly for cargo. At the same time, social distancing directives were being instituted nationwide. HAECO saw an opportunity and quickly developed solutions that enable airlines to carry cargo and passengers at the same time, optimising passenger and cargo yield. The key to the solution is using packages to distance passengers, while maintaining proper weight and balance requirements.

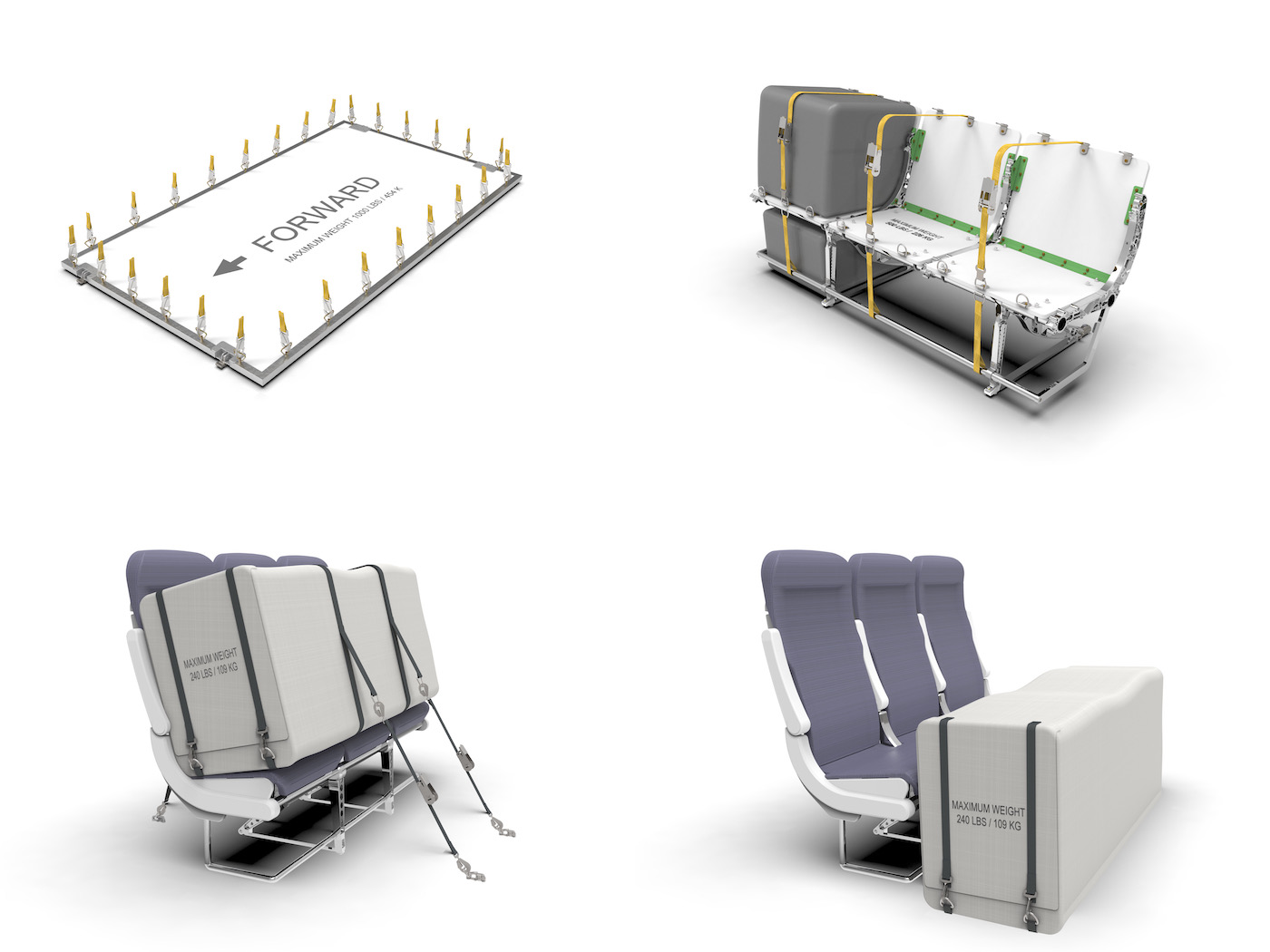

The company says it moved four unique solutions from concept to offerable in less than a month. The solutions will be certified through a Supplemental Type Certificate (STC) and HAECO says they are unique in the amount of weight that can be carried.

The palletised variant can hold 1,000 lbs (454kg), while the all-in-one seat frame can hold 500 lbs (227kg), and the seat and floor storage systems can each hold up to 240 lbs (109kg). These options give airlines specific load authorisations and the capability of carrying larger items in the cabin that otherwise would have been stored in the aircraft’s belly, except for hazardous materials.

The hardware builds upon existing seating and interior technologies and can be delivered in four to six weeks. Variants can be combined for both single- and twin-aisle aircraft to achieve an ideal operational payload. The installation process follows techniques used for economy seating, which can be accomplished quickly and without the need for special tools, according to the company.

Doug Rasmussen, president and group director of HAECO Cabin Solutions stated, “We are pleased with the strong interest we have already seen from airlines and leasing companies, and are delighted that we can offer a quick, cost-effective solution to maximise yields during this challenging time.”