These are exciting times for FACC, with recent major announcements including a deal with AVIC to strengthen its direct airline business, a €500m contract with Airbus for the delivery of overhead stowage compartments and ceiling panels for A320 Airspace interiors, and a deal to supply the entrance area for the entire A320 aircraft family. The latest development is that the Austria-based company has entered into a three-year research project in the field of industrial inspection robots. Named Spirit, the project will see FACC work with Austrian robotics specialist, Profactor, and eight international scientific and industrial partners from Austria, Germany and Italy to develop a new generation of inspection robots that can undertake a wide range of inspection tasks without programming effort.

“The goal of the project, in line with our aim of advancing robotic solutions, is to replace the time-consuming and highly skilled task of robot programming with simply configuring the inspection task,“ explained Helmuth Hoeller, director of the NDT division at FACC. When a new component or a complex shape is to be inspected, the main challenge with inspection robots is to plan the robot motion path in such a way that the whole surface of the component is inspected. This process is usually carried out by specialists and is therefore resource and time intensive. Spirit aims to move this task from the programming level to simple configuration, thereby saving time and reducing the resources required. FACC, with its extensive experience in industrializing innovative solutions, is expected to integrate the results of this project directly into the production workflow.”

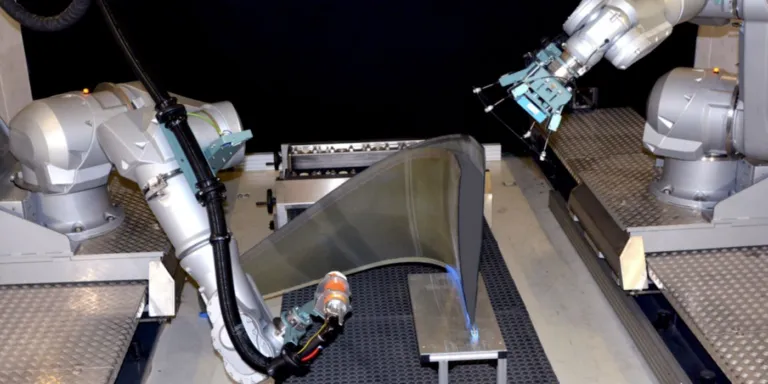

Such robots can automatically inspect anything from aerostructures to stowage compartments, with the software being designed to be able to switch between different inspection technologies and parts types quickly and easily. Operators need only input a CAD model of the relevant component into the inspection robot, along with the CAD model of the work cell in order to avoid unwanted impact during inspection. Given this information, the system will process the selected inspection technology and automatically generate an inspection program for the task.

Another planned feature of the system is that it will be able to autonomously optimize the inspection process in real time while it is running. Should the system detect an unknown deformation not accurately represented in the CAD model, or sense a minor misposition of components, or calculate that a sensor adjustment is necessary for an X-ray inspection (to align with the orientation of the honeycomb core in a composite part, for example), the required optimization will be performed automatically.

When the project is complete and the technology implemented, FACC anticipates benefits including increased efficiency by replacing task programming with task configuration; multi-faceted and more accurate descriptions of possible deviations; and optimized feedback to planning and design for possible adjustment of tolerances, which in turn will help to reduce unnecessary additional work.