CRP Technology, a specialist in composite materials for additive manufacturing in sectors including aerospace, has responded to the Covid-19 crisis by developing and manufacturing several functional prototypes of valves for reanimation devices, and link-components (known as ‘Charlotte valves’) to be used in emergency respiratory masks for assisted ventilation.

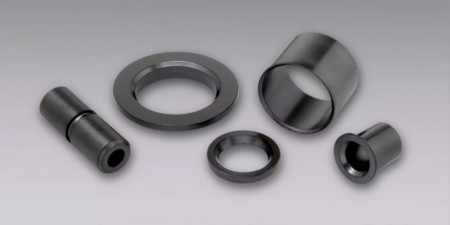

The company’s in-house rapid prototyping department used a 3D-printing technology called HSS (high-speed sintering) and Windform P1 isotropic material for the manufacture of both types of components.

Franco Cevolini, vice president and technical director of the Italian company explained that Charlotte valves are link-components for emergency ventilator masks, an idea realised by Dr Renato Favero at Isinnova (an independent Italian research institute) for the adjustment of snorkelling masks.

“Isinnova has decided to urgently patent the link valve (Charlotte valve) to prevent any speculation on the price of the component. They clarify that the patent will remain free to use, because it is in their intention that all hospitals in need could use it if necessary,” stated Cevolini.

It should be noted that neither the mask nor the link are certified, and their use is subject to a situation of mandatory need. Usage by the patient is subject to the acceptance of use of an uncertified biomedical device, by providing a signed declaration.