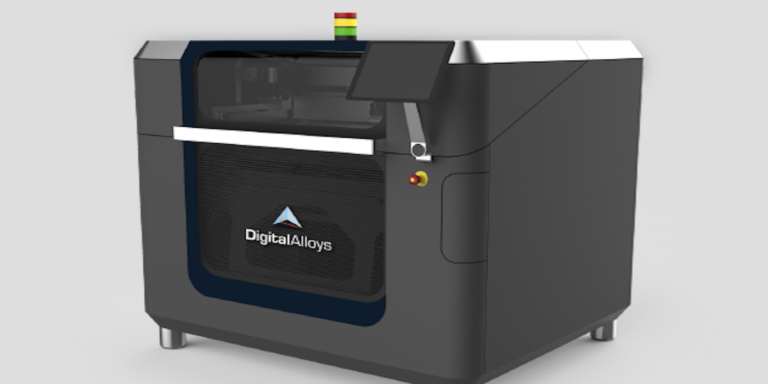

Boeing has announced an investment in Digital Alloys, a Massachusetts-based company that develops high-speed, multi-metal additive manufacturing systems for producing 3D-printed parts for industries including aerospace. The investment forms part of a a US$12.9 million Series B financing program led by G20 Ventures and joined by Boeing HorizonX Ventures, Lincoln Electric and prior investor, Khosla Ventures.

Boeing is no newcomer to 3D printing and its time- and cost-saving benefits, with more than 60,000 3D-printed parts flying on its various space, commercial and defense products. The attraction to Digital Alloys is its Joule Printing technology, which can rapidly combine multiple metals into each part, a process which is claimed to enhance thermal, electrical, magnetic and mechanical properties. The process allows metals such as titanium and high-temperature alloys to be 3D-printed for parts that could be used on Boeing products. The process is claimed to offer lower cost and complexity than powder-based 3D-printing systems, and higher resolution than other wire-based 3D-printing techniques.

“Our investment in Digital Alloys will help Boeing produce metal structural aerospace parts faster and at higher volume than ever before,” said Brian Schettler, managing director of Boeing HorizonX Ventures. “By investing in companies with emerging additive manufacturing technologies, we aim to strengthen Boeing’s expertise and help accelerate the design and manufacture of 3D-printed parts to transform production systems and products.”

“Our novel Joule Printing process is faster, more cost-effective, and more reliable than other approaches,” added Duncan McCallum, CEO of Digital Alloys. “Partnering with Boeing will make us a smarter, stronger company.”