Supernal, a US-based subsidiary of Hyundai Motor Group developing an eVTOL, has revealed the cabin design, with influences from automotive and biomimicry – a butterfly in this case. Supernal partnered with Hyundai’s design studios to create the cabin concept as the company works to certify its eVTOL for commercial use in the USA starting in 2028 – and in the EU and UK shortly after.

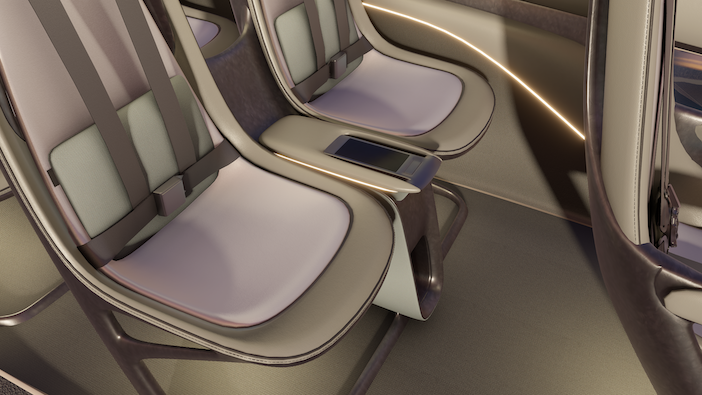

The five-seat cabin concept draws upon automotive design processes and materials to optimise the passenger experience and price point. The team of engineers and designers applied the automotive industry’s reductive design approach to create the lightweight cabin interior, which is made of forged carbon fibre. Ergonomically contoured seats offer a cocoon-like environment for passengers, again referring to the butterfly inspiration. Deployable seat consoles mimic automobile centre consoles and provide a charging station and stowage compartment for personal items.

Other features include grab handles built into the cabin doors and seatbacks, to assist with ingress and egress. A combination of lighting – including overhead lights inspired by automobile sunroofs – adjusts with the various stages of flight to emulate a ‘light therapy’ effect. The cabin layout draws further on automotive space innovation with a minimised bulkhead, which allows for generous headroom and package functionalities.

The cabin concept incorporates sustainable materials such as advanced recyclable carbon fibre reinforced thermoplastic (CFRP), durable plant-based leather, recycled plastic fabrics, and responsibly sourced woods. The seat frame is constructed from excess raw material created during the airframe manufacturing process.

“Supernal is partnering with Hyundai Motor Group’s top automotive designers to develop our eVTOL vehicle for manufacturability and widespread public acceptance,” said Jaiwon Shin, president of Hyundai Motor Group and CEO of Supernal. “We are taking the time to create a safe, lightweight commercial eVTOL that provides our future passengers with the security and comfort they find in their own cars.”

An Advanced Air Mobility value chain

Beyond the vehicle, Supernal is collaborating with external partners and the Hyundai Group’s more than 50 affiliates – which span automobiles, automotive parts, construction, robotics and autonomous driving – to co-create an Advanced Air Mobility (AAM) value chain.

“In order for Advanced Air Mobility to become a wide-spread mode of transportation, every detail – from the passenger experience to regulations and infrastructure – needs to be addressed from the start and work in lockstep with one another,” said Shin. “Leveraging Hyundai Motor Group’s mobility capabilities, Supernal is investing time and resources upfront to ensure the industry can scale to the masses in the coming decades and reach its exciting potential.”

Air mobility beyond urban markets

Hyundai Group is working beyond the urban air mobility sector, to develop a family of electric air vehicles, with a corresponding expansion in the surrounding value chain.

Complementing Supernal’s battery-powered eVTOL vehicle designed for intra-city passenger journeys, with a planned launch date of 2028, Hyundai’s Korea-based division focused on regional air mobility is developing a hydrogen-powered mid-sized vehicle for regional city-to-city cargo and passenger journeys. The division plans to launch service of its hydrogen vehicle in the 2030s.

Supernal and the Korean division are partnering with Hyundai Group’s manufacturing innovation teams across the globe to create a robust, high-rate AAM manufacturing process designed to produce electric air vehicles at scale – at an increasingly affordable price-point – over the coming decades.

“Hyundai Motor Group is working to leverage synergies between automotive’s high-rate manufacturing capabilities and aerospace’s high certification standards to build the foundation for everyday use of passenger and cargo air vehicles,” Shin said.