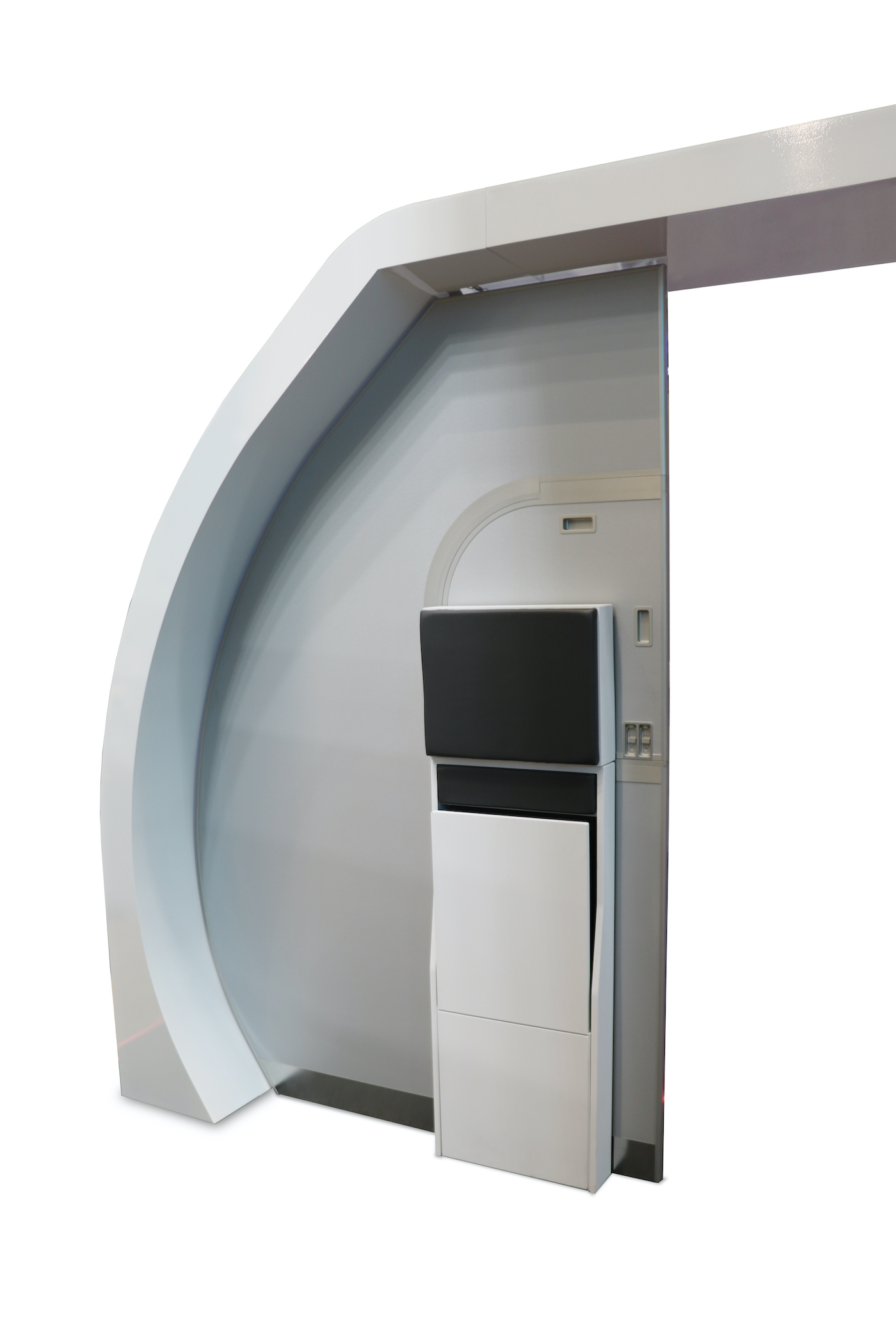

Following a qualification and approval programme, Bucher’s Bionic Partition, developed with Airbus, is now being installed as a line-fit and retrofit option in A320 aircraft. The multifunctional partition, fitted in the rear Door 4 area, separates the passenger area of the cabin from the crew’s working area towards the rear galley and the toilets.

As well as serving as a visual partition, the unit forms part of the safety architecture within the aircraft cabin, supporting a wall-mounted cabin attendant seat and various holders for emergency equipment such as fire extinguishers, smoke masks, oxygen supplies and life jackets.

The ‘Bionic’ in the name refers to construction methods and mechanisms from biology being analysed and the findings transferred to technology. According to the ethos, if it is possible to recognise the interplay of individual elements in an overall design, waste can be reduced and previously unused potential can be released.

After more than two years of development at Bucher, the result is a sandwich panel with a honeycomb core and carbon fibres (CFRP). As the company says, the panel is ‘radically rethought and unconventionally constructed’, with a multi-layer composite of various different fibre orientations. These orientations are used over the entire surface or locally, with the wall thickness of the sandwich remaining the same.

Thhe company says that bionic construction can enable weight savings of more than 30% to be achieved, as less material is used than in conventional designs.

You can read more about the development of lightweight cabin structures HERE.

While a reduction in weight could be achieved, in order to be deemed airworthy the bionic structural concept of the partition still had to withstand varying static and dynamic loads, as well as load changes. To obtain approval, the structure was not allowed to fail under dynamic accelerations of more than 16g in the direction of flight.

The engineering teams also had to take into account the flexible positioning of add-on parts in zones to be defined. The lightweight structure had to allow a low structure weight with the highest possible payload, enabled by the innovative fibre composite sandwich panels.

Beat Burlet, CEO of Bucher Group, said of the first installation at Airbus,”We are very proud that our lightweight Partition is now part of the safety architecture within the aircraft cabin and is being used for the first time in daily flight operations. The enormous weight savings that we have achieved with this product are the result of several years of development. The first delivery to an aircraft manufacturer and finally to an airline fills us with immense pride.”