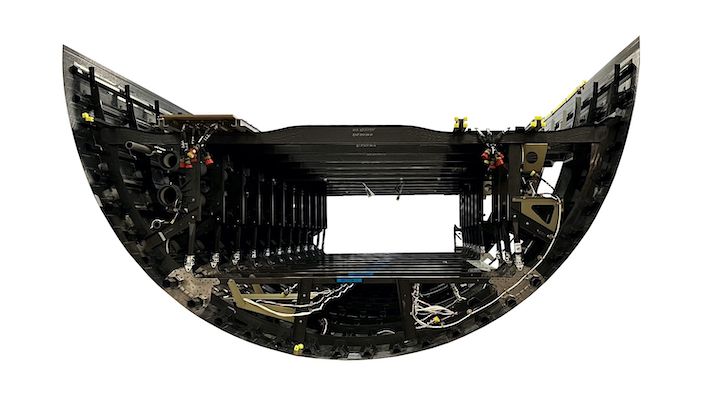

A consortium of aerospace companies report they have successfully manufactured one the world’s largest thermoplastic components as part of the Multi-Functional Fuselage Demonstrator (MFFD) project led by Airbus. The 8m x 4m composite structure – delivered under the Clean Sky 2 STUNNING (SmarT mUltifuNctionNal and INtegrated thermoplastic fuselaGe) project – will act as the lower half of the fuselage demonstrator. The structure is intended to help show how the use of thermoplastic composites can help realise a next-generation fleet of aircraft with the same strength and durability as those made of aluminium, while drastically reducing the fuselage recurring cost, as well as the overall weight of aircraft and the subsequent emissions.

The companies involved in designing and manufacturing the composite structure are GKN Fokker, NLR – Netherlands Aerospace Centre, Delft University of Technology and SAM|XL The aerostructure consists of more than 400 thermoplastic fibre-reinforced parts, as well as thousands of spot welds and hundreds of meters of continuous welds. The lower half of the fuselage will be joined at Fraunhofer IFAM in Stade, Germany, with the upper half made by the German Aerospace Center (DLR) Institute of Structures and Design in Augsburg.

The MFFD project aims to demonstrate that it is capable of the High Rate Production (HRP) of a minimum of 60 aircraft per month (up to 100 aircraft), reduce the total fuselage weight by 1 ton (10%), and reduce the total fuselage recurring cost by €1m (20%). STUNNING contributed to these objectives by showcasing novel thermoplastic manufacturing and joining technologies, as well as modular manufacturing techniques and automation.

GKN Fokker was responsible for the assembly of STUNNING, which consisted of a skin module and a floor grid module. The skin module featured a skin made by NLR as a single part using automatic fibre placement, 38 stringers from Xelis made using continuous compression moulding, some of which joggled by NLR, 208 injection-moulded clips produced by the ECO-CLIP consortium, and frame sub-assemblies.

The floor grid module included floor beam sub-assemblies, with passenger floor beams made by automatic fibre placement. Both frame and floor beam sub-assemblies were made by GKN Fokker. The floor grid was fully equipped with various systems before installation in the skin module.

Arnt Offfringa, director of the Global Technology Center NL at GKN Aerospace said: “This breakthrough project, which began in 2017, has significantly advanced our understanding and accelerated the development of thermoplastic technologies for large and complex aircraft parts. It has showcased the potential for industrial-scale application of robotic welding in the assembly of thermoplastic aerostructures. The partnership approach to STUNNING has also been a great success, showing how much progress can be made when working together. Collaboration projects such as this will be vital as we continue to push the boundaries of technology in order to meet our sustainability targets.”

The demonstrator was assembled in SAM|XL at the TU Delft Campus, where a 10 x 11 x 4m ultrasonic welding robot was built from numerous machine parts and software components supplied by European partners. Team SAM|XL was responsible for the integration of the robotic welding cell and the development of smart control and programming methods.

The TU Delft team say that valuable lessons were learned in the process, related to ‘design for automated assembly’. In a joint effort, rapid energy-efficient ultrasonic welding technology was scaled-up from the lab at the Faculty of Aerospace Engineering to become an industrial-scale solution for dust-less assembly of the demonstrator, involving 1,600 structurally sound spot welds. Further maturation of this assembly technology will be accelerated in SAM|XL’s new robotic welding lab.