29th November saw Unum Aircraft Seating officially open its factory at One Kelvin Lane in Crawley’s Manor Royal aerospace hub, close to London Gatwick airport. The company was previously based in nearby Weybridge, with the move to the larger premises in Crawley forming part of the company’s growth strategy.

The opening follows the company’s Part 21G Production Organisation Approval (POA) regulatory approval from the Civil Aviation Authority (CAA) in June, following an audit and assessment of the facilities, processes and systems.

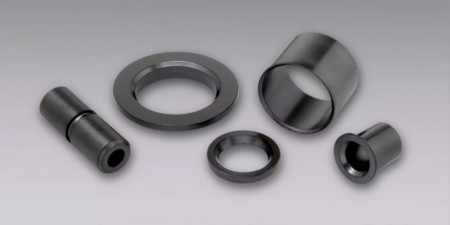

The main activities at the facility will be the production of business-class seating. The range currently comprises the Unum One– a herringbone design available in widebody, high efficiency and single-aisle variants – and the Unum Two staggered seat, both designed with partners including the Acumen design studio. A key feature is the patented Scimitar seat mechanism, which enables a range of passenger movement including a Zero Gravity position.

The company also secured additional funding in February 2023, from Origin Capital and the Low Carbon Innovation Fund 2 (LCIF2).

The facility is surrounded by several big names in aviation, including Boeing, Virgin Atlantic, the CAE, Thales, Collins Aerospace, L3Harris and Adams Aviation. Another local building is the former HQ of Acro Aircraft Seating – a site familiar to Unum’s executive chairman and CEO, Chris Brady, as he was the company’s co-founder and managing director until 2019, following its acquisition by Zhejiang Tiancheng Controls.

You can find out more from Chris Brady, and see details of Unum’s current seat designs HERE.

Keeping the local feel, most of Unum Aircraft Seating’s materials and components will be sourced within the UK, from its suppliers such as interiors and upholstery specialist, Sabeti Wain Aerospace. This local strategy helps ensure a stable supply chain, benefits sustainability, and ultimately on-time delivery of seats. The few imports will come from Germany: seatbelts and restraint systems supplier, Schroth, and electrical seat actuation system supplier, Bühler Motor.

Representatives from these and other suppliers were among the attendees at the official launch party for the factory, as well as key Unum executives, including Chief Operating Officer Tania Trucchia (also a technical expert with experience at Alitalia, AJ Walter Aviation and Acro); VP of business development, Alan McInnes (previously of Caeli Nova and Acro); chief technical officer, Mark Hacker (previous roles include head engineer roles at Collins Interiors, Safran Seats GB and Nordam); and quality director, Beata Paliwoda (highly experienced in project and environmental management, and another Acro alumni).

Other guests included representatives from the Green Cabin Alliance and the UK Department for Business & Trade. A familiar face was on hand to cut the ribbon: Ben Bettell, who has worked with… well, pretty much everyone in the aircraft interiors sector.

Ben Bettell said at the event: “I am proud to have been involved with Unum since its inception. Unum not only has a world-class business seating product, it is also home to experienced staff and now excellent premises to produce and deliver its seat from – premises that I am pleased to open officially today.

“Unum comprises a group of talented people with a proven successful visionary as a leader, and this results in an amazing customer-centric business-class seat.”