The Caon Design Office in Australia has collaborated with Woolmark to develop Modulo, an aircraft seat concept designed to solve issues including weight reduction, sustainability, and the need for frequent cabin refreshes, while delivering wellbeing, hygiene and privacy for the passenger.

In partnering with Woolmark, a global authority on Merino wool, Caon identified Australian Merino wool as the perfect material for this project due to its next-to-skin softness, strength, innate versatility and technical benefits. Merino wool is also a 100% natural, renewable and biodegradable fibre.

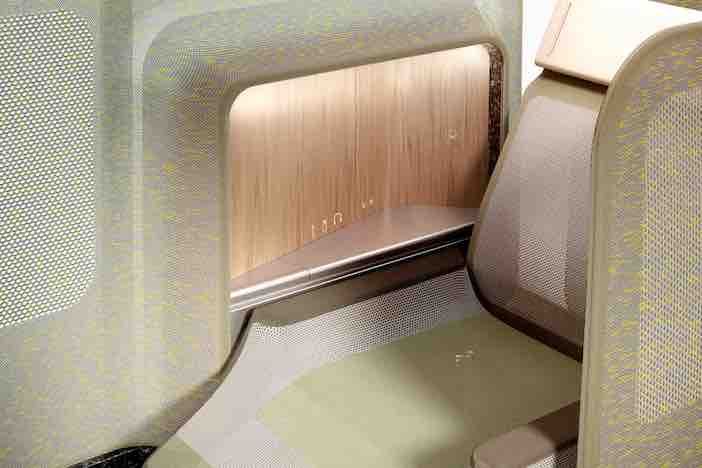

The physical embodiment of the concept hints at conventional layouts of first-class aircraft seating, but without being confined to a particular travel class. The Caon studio team says that Modulo represents an exploration of materials, shapes, and concepts rather than a specific proposal for a configuration and features.

“In exploring how to expand the capability of the wool fibre within the airline industry we address a major bugbear of airlines in that they have to spend huge sums of money and time in changing the feel of their cabin interiors,” said David Caon, founder of the studio. “Passengers benefit too, by having more of this wonderful material, which breathes and allows us to play with light and opacity to create new scenarios for privacy and relaxation.”

Designed differently

Modulo is not merely a design study, as Caon says it represents a leap forward in aircraft interior design, focusing on passenger experience, environmental impact, and operational efficiency.

Embracing an aesthetic inspired by organic forms, Modulo reflects an appreciation for the interplay between material properties and design outcomes. This approach, which Caon says is reminiscent of Mario Bellini’s work with Olivetti, celebrates the beauty that arises from the natural shapes and textures of materials.

You can see an animation of the concept HERE.

Smart technology

Modulo’s design is integrated with sensors and technology that actively monitor and regulate seat temperature for optimal comfort. The systems also prompt passengers to move periodically in order to help mitigate health risks associated with prolonged immobility, such as deep vein thrombosis (DVT).

Futuristic fabrication

The concept features a 3D-knitted wool blend membrane, which is a key part of the design as the wool is elevated from being a surface material to being the primary touchpoint, offering a distinctive tactile and visual experience. The designers also claim the membrane enables weight reductions.

In contrast to some seating products that rely on rigid composites or plastics for partitions or support, Modulo features wing-like woollen elements, thereby concentrating on a single material as the central theme of the design.

A lightweight yet robust framework of titanium, aluminium and carbon fibre forms Modulo’s structure and supports its distinctive fabric membrane. This semi-transparent skin, shaped by advanced 3D-knitting techniques, forms a wool blend that is structural yet pliable. Carbon and elastic polymers integrated into the fabric give dynamic flexibility, allowing the seat to transition smoothly from an open space to a private enclosure. The knitting technology employed in Modulo allows for the integration of wadding within specific sections of the fabric, reducing the reliance on traditional foams.

“By harnessing the benefits of Merino wool, such as breathability, moisture-wicking properties, and luxurious softness, Modulo demonstrates how Merino is uniquely positioned to elevate the future of travel through unparalleled comfort and enhanced sustainability. This collaboration with Caon Design Office underscores a shared commitment to driving innovative solutions with eco-conscious design principles.” said John Roberts, managing director of Woolmark.

Aesthetic efficiency for airlines

Modularity is a defining feature of the concept, allowing airlines to adapt their cabin aesthetics with ease. The design supports a seamless transition of the cabin ambiance to reflect themes such as the changing seasons or the latest branding initiatives.

Aided by a sophisticated quick-release mechanism, the wool membrane skin can be interchanged as easily as a standard seat cover. This adaptability reduces downtime and also provides a dynamic passenger experience with each season, ensuring that the cabin environment remains contemporary and engaging without requiring the airline to ground the aircraft for lengthy periods, or to reconfigure and refit seats.

Additional applications

The Modulo design can extend beyond aviation, offering a versatile seating solution adaptable to future modes of transportation. Its lightweight structure and modular nature are suitable for the evolving landscapes of mass transport, hyperloops, autonomous vehicles, and electric aircraft.