Aircraft cabin interior design is one of the few ways an airline can influence the brand experience of its passengers, but it’s no easy task. Careful planning and coordination –not to mention significant expense – go into design and implementation. Throughout a single project, airlines, designers, suppliers, manufacturers and integrators all play a key role in getting every detail right.

Adding to this challenge is the fact that coordinating colour across different materials – and even the same materials – is nearly impossible with eyesight alone. Did you know that lighting, altitude, noise and even stress levels can influence how you see colour?

Thankfully, the right digital colour tools and processes can help streamline the cabin design process, especially when multiple component and materials manufacturers are involved. Here are a few things to know about colour control and cabin design projects.

Colour perception is subjective

Colour is an integral component of cabin design. You’ve probably heard how colours can evoke different emotions or even impact behaviour. So, it’s no wonder why so many airlines use interior colour palettes that emphasise shades of blue – a calming colour that can help counteract some of the stress and anxiety often associated with air travel.

However, getting colour right is far from a simple process. One of the primary factors influencing this is the highly subjective nature of colour perception. Inconsistencies in light source, different backgrounds, even altitude and noise can affect how we see colour. An individual’s age, certain medications, mood and other factors can also impact colour perception.

These differences in colour perception can lead to costly mistakes, wasted time and plenty of confusion. Strict flame, smoke and toxicity requirements that come with airline interior materials make them especially expensive. Having to re-do an airline’s carpet colour, for example, can set a project back tens of thousands of dollars at a minimum – and that’s before factoring in the cost of project delays.

How digital color management can help

When getting colours right is critical, many industries overcome the shortcomings of visual colour evaluation by using specialised equipment, like colour measurement devices and software for formulation and quality control , to digitally measure and communicate colours –whether it be across the same materials or a range of materials.

Countless industries, including apparel and textiles, paints and coatings, automotive and plastics, rely upon digital colour management to get colour right. These tools capture accurate, repeatable colour measurements that can be communicated to all teams involved in a cabin design project, regardless of location, individuals’ colour perception or other influencing factors.

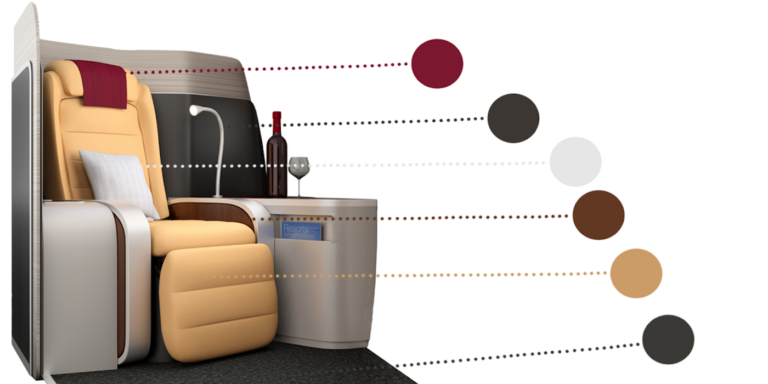

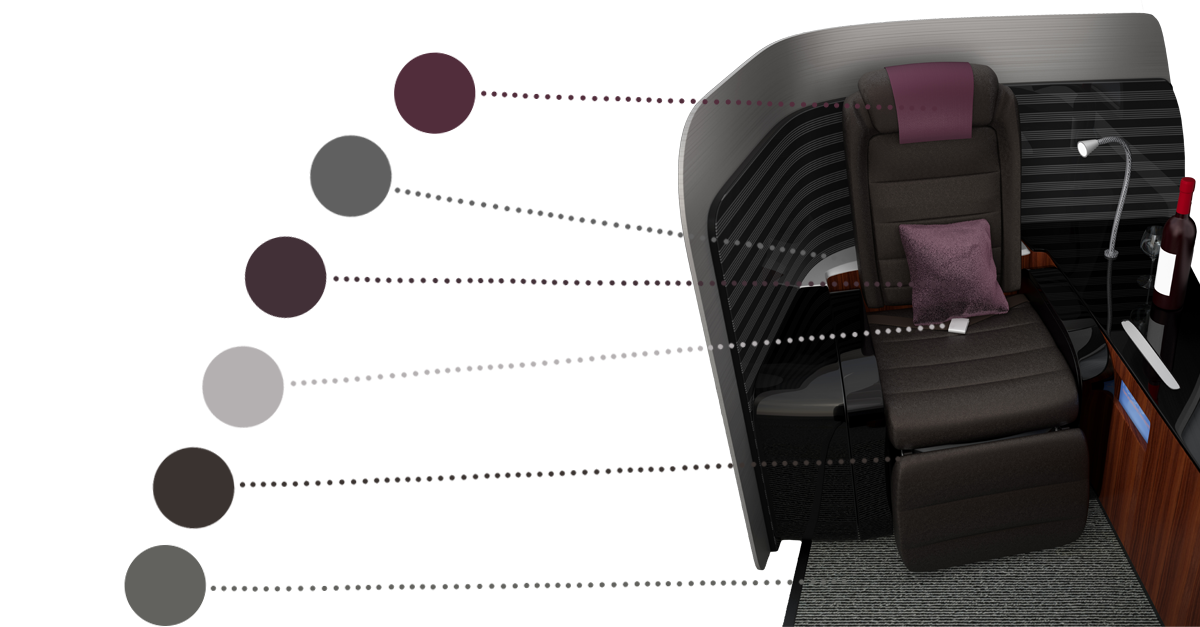

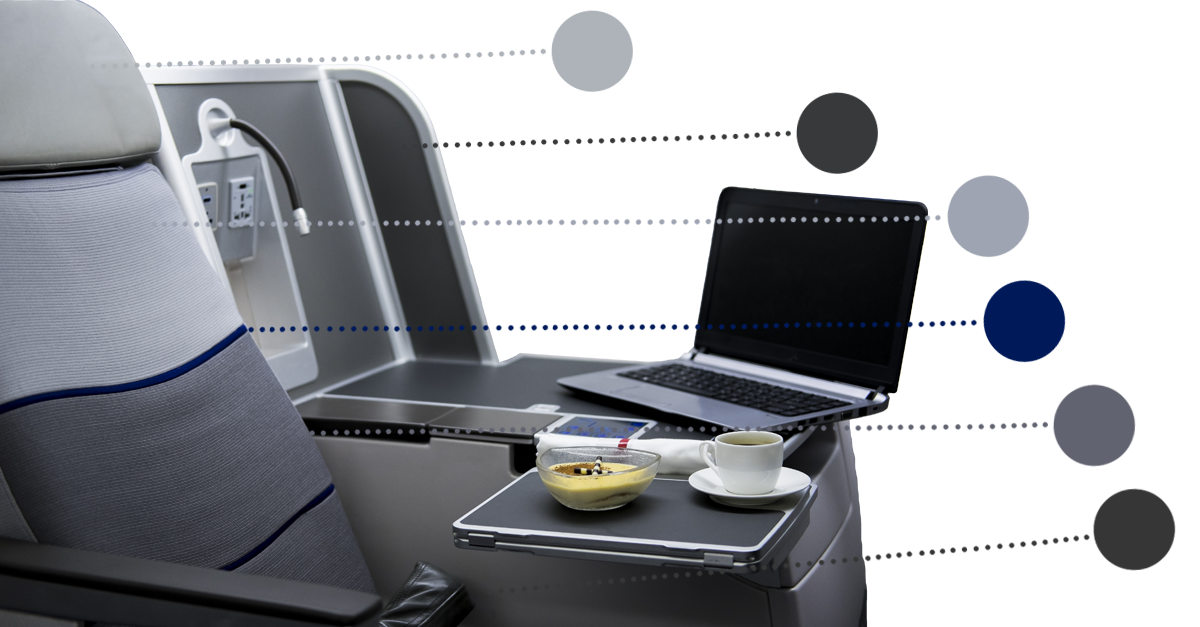

Within the airline interiors industry, there is the added challenge of coordinating colour palettes across a wide range of materials. Say you want to coordinate the colours of cabin seating, carpet and bulkheads. From the carpeting and plastic to the leather and fabric, each element of an airline interior needs to work together seamlessly.

The problem? The colour composition required to achieve a match changes from one material to the next.

Thankfully, today’s technology and software can readily produce accurate, repeatable digital colour measurements across nearly any surface or material, including multi-coloured, textured materials. That means, when you order flooring for your new aircraft OEM program, it arrives in the right colour the first time. There is no need to delay projects, air freight new materials or otherwise disrupt your production schedule or budget.

Another challenging problem is ensuring an aircraft cabin retains the desired appearance when, over time, various components of an aircraft interior need to be replaced. However, if every company working on a cabin design project were to adopt digital colour tools and use compatible instruments and uniform processes and procedures for measuring and communicating colour, it could reduce the risk of human error and ensure that all cabin materials, new or old, blend seamlessly together.

The impact of colour can be felt in all aspects of the airline interiors industry. With so much on the line – pressure to meet deadlines, mounting raw material costs, labour and talent shortages, global competition – there is little room for error. With the right digital tools and an integrated colour management program, the design process for commercial airline interiors can become seamless.

About the author

Diane Geisler is VP of marketing for Datacolor. In a previous role, Diane worked on commercial airline interiors for Schneller, the world’s largest supplier of interior laminates for commercial airlines, giving her unique insight into the nuances of colour management for the airline interiors industry. As a former chemical engineer, Diane’s career at Datacolor has spanned company departments and regions of the world. Datacolor is a global leader in colour management solutions and provides software, instruments and services to assure accurate colour of materials, products and images. Leading brands, manufacturers and creative professionals have used Datacolor’s solutions to consistently achieve the right color for more than 45 years. Industries served include textile and apparel, paint and coatings, automotive and plastics, as well as photography, design and videography. For more information, visit: datacolor.com.