For an OEM, a lavatory should have its own industrial design, be as light and cheap as possible, and suit their industrial and contractual needs. For the airline, the prime need is revenue space (aka floorspace), with favorable spares availability, as well as branding considerations for premium airlines. Passengers want cheap flight tickets and ideally do not need the lavatories at all; if they do, they’d like them to be just as their bathroom at home: comfortable, spacious and clean.

These three stakeholders thus have very different requirements. So how can future lavatories fulfil as many as possible?

First, streamlining developments. Most industries develop primarily for the OEM, as lavatories have a small retrofit market. But OEM developments are typically burdened by thousands of non-certification relevant requirements. By developing directly for the retrofit market, we can be three times faster, at half the costs, while improving spaciousness, functionality and innovation.

Second, space. Using smaller (non-OEM) equipment and user-centric, ergonomic designs, we can free 5-10in of interior space for the passenger, reducing lavatory width by as much as and increasing airline revenue space – at limited to no additional costs. Coupled with well-placed lighting and directed air streams, the shrunk lavatory can feel larger than a current one.

”As long as we try and cater to OEMs, airlines and passengers alike, we will not see true innovation at affordable prices. Instead, let us focus on those who actually operate and use the lavatories: airlines and passengers”, says Sebastian Tivig, creative lead at Diehl Aviation.

Densification³

Airlines need floor space – how can we deliver without compromising passenger comfort? And how can we fit disabled people into the picture?

The current meta-trend for lavatories is simple: smaller and smaller. To the point where a slightly bulkier person cannot enter and where even a slim person thinks thrice before using the lav.

Diehl Aviation has developed its own solution for ultra-dense lavatories, paving the way for the mid-term future. In-depth ergonomic analysis enabled up to 8in of internal space to be freed-up compared to normal lavatories, and around 3in compared to current OEM slim lavatories. We widened the door at shoulder height for maximum egress/ingress comfort and even fitted a PRM mode, creating the Space³: three lavatories fitted in the same space as previously two, PRM enabled, and able to fit a 95 % American male.

But that is today – what about tomorrow? When it comes to densification, we still have a few tricks up our sleeve and can likely gain another inch or two – but that is the limit. In the end, you still have to fit the passenger. So instead of finding solutions to shrink the space itself, we have to think outside the box, using the lavatory to gain space in other areas: storage during take-off and landing, integrating a front-row monument, collapsible monuments (using door space during flight), under-floor (cargo compartment) monuments and the like.

This still doesn’t mean that passengers like or accept the experience. And this is arguably the area that needs the most work. “We focus on a number of mid-term solutions: the lavatory with touchless functions, e.g. seat, lid, water, waste flap and door solves hygienic issues,” says Helge Sachs, SVP of product innovation at Diehl Aviation. “Coupled with self-cleaning floors and toilet seats – including automatic disinfection – as well as active smell reduction we can alleviate the passenger’s main issue: the perception of a dirty lavatory.”

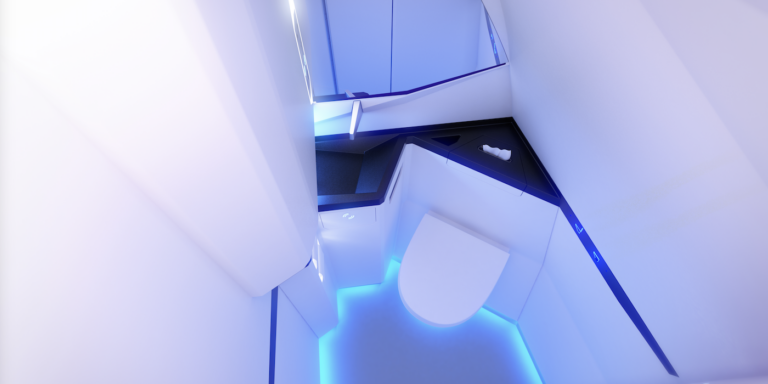

The use of many small, light-weight, low-power and low heat LEDs allows to increase the feeling of spaciousness at small cost. Directed airflow (think of a summer breeze) increases comfort. Sounds (birdsong, running water) evoke nature, helping the passenger forget he’s in an aircraft lavatory.

Hence, the mid-term lavatory envisioned by Diehl Aviation is floor-space optimized, with a highly technical interior, providing a comfortable, clean and modern passenger experience.

Future vision: a short story about how Diehl envisages the future lavatory experience, 10 to 20 years from now

Mr Meier, aged 67, retired and well-off, flies a typical six-hour leg to his vacation destination. He needs to use the onboard lavatory more often than when he was younger – but he is no longer anxious about that.

While ultra-slim lavatories were the norm in the 20s, the ageing population brought about a change in cabin design again, and in the premium economy segment they went back to their old sizes. And many changes did come to the interior, making the lavatory experience actually pleasant.

Mr Meier walks up to the lavatory door, which opens automatically, revealing a space-optimized, well lit, clean interior. As he walks in, the door closes and latches behind him, with a soft vocal welcome. The lights become brighter, more bluish. A soft breeze of warm air blows gently. There are handholds for Mr Meier, coat hooks and clear symbols showing him where everything is. As he turns towards the toilet, the lid opens automatically to reveal a disinfected, clean seat.

Afterwards, the lid closes by itself, and the toilet flushes itself. The light around the water faucet is stronger now, and as Mr Meier washes his hands, automatic air extraction and disinfection systems remove odors, clean the toilet seat and make sure there are no bacteria left.

Feeling refreshed, Mr Meier turns towards the door, waves his hand above the lock and the door unlocks and opens, as a friendly voice wishes him a pleasant remainder of the flight.