In the aerospace sector reducing weight is constantly one of the greatest priorities. Due to the high technical requirements, economic and legislative drivers, and relatively deep pockets, aerospace is often the first significant adopter of emerging lightweight materials. This blog highlights some of these materials at different stages of technology readiness and suggests what their initial application will be.

The world of advanced materials is extensive, but making the jump from academic or R&D labs to commercial success is a tortuous and challenging path. Motorsport and sporting goods often provide initial market entries due to lower regulatory barriers, but in many cases, the first industry that allows capacity to scale-up and notable revenues to emerge is the aerospace and defense sector. Ceramic matrix composites (CMC), metal matrix composites (MMC), polymer aerogels and CNT-yarns are examples of those emerging materials and will be discussed here. Another key trend is the evolution of polymer composites which was discussed in a previous article.

Ceramic Matrix Composites (CMC)

CMCs are right on the cusp of rapid growth. Both Ox/Ox (typically alumina/alumina) and SiC/SiC varieties have received significant investments and will begin to reap the rewards. The most significant is the use of continuous ceramic fibers, of which the main players (brand or subsidiary in parenthesis) are 3M (Nextel) and Unifrax (Saffil) for alumina fibers and NGS Advanced Fibers (Nicalon) for silicon carbide fibers.

The aerospace roles are dominated by those that require the highest temperatures, which results in the early uptake being in jet engines and exhaust nozzles. The material is not only lighter than the superalloys it is displacing, but also has an improved efficiency in the cooling requirements.

Metal Matrix Composites (MMC)

Metals have seen their share of aerospace structures gradually diminish, but emerging alloys and the growth of additive manufacturing give it an improved outlook and is helping the fight back against polymer composites. Aluminum alloys, specifically lithium, beryllium, and scandium varieties, and other alloys such as titanium aluminide and high-entropy alloys all feature heavily when considered with aerospace.

MMCs are also having a resurgence after many false-starts, driven by technical advancements, predominantly surrounding the additives, and are in demand as many other solutions become exhausted.

Utilisation within the aerospace and defense industry is coming from the use in highly wear-resistant parts, such as gearboxes, or in the ability to enhance aluminum. Aluminum can not only benefit from an enhanced strength and stiffness, but also the performance at elevated temperatures and improved corrosion resistance. The long-term proposed applications could be in parts as significant as landing gear, exemplified by a recent grant led by Safran utilising Alvant (previously CMT) aluminum composite technology.

Polymer Aerogels

When many people think of aerogels they imagine transparent brittle silica monoliths, but the commercial reality is very different. The industry is dominated by silica blankets due to their superior insulative properties, but there is an emerging type that is highly relevant for aerospace. Polymer aerogels are highly porous continuous networks (typically polyimides, polyureas, or polyurethanes) and can be made as monoliths or films through either supercritical or ambient pressure drying methods. Unlike their silica counterparts, excluding some minor exceptions, monoliths are not brittle and display good strength.

Aerogel Technologies produces a material called Airloy, which not only is lighter weight compared with other polymers given the high porosity, but also offers significant insulation and soundproofing. There are significant links for aerospace interiors looking to employ this material. Outside of interiors, the role of polymer aerogel for antennas and with composite material show aerogels has much more versatility and potential than many are aware of.

CNT-yarns

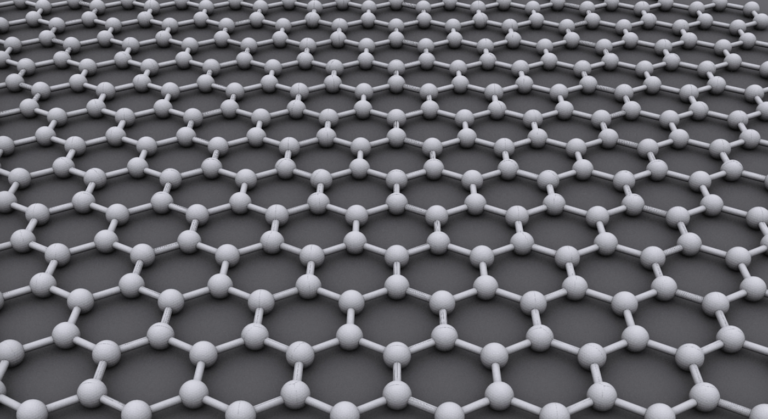

The role of nanomaterials is highly relevant to aerospace, such as graphene or the use of nanomaterial in polymer composites. However, an increasing opportunity comes in the use of pure continuous CNT-yarns.

There are a variety of routes in forming CNT-yarns, including CVD processes and wet, dry or electro-spinning methods. The electrical (ca. 1/10th conductivity copper) and mechanical properties (ca. 10x tensile strength of copper) are ever improving, and more young companies are forming. The interest from aerospace is growing and the proposed applications vary from data transmission cables, EMI shieldings and motor windings.

IDTechEx has released a new report on additive manufacturing and lightweight materials for aerospace and defense 2018-2028. The analysis contains roadmaps, forecasts, company profiles, and technology assessments in one of the key sectors in the adoption of early-stage technologies.