As face coverings, hand sanitiser and personal protective equipment (PPE) have become part of daily routines, one safeguard has kept American’s customers and team members breathing clean air at 30,000 feet. High-efficiency particulate air (commonly known as HEPA) filters have purified the air on American’s entire mainline fleet – and most regional jets – since the late 1990s. HEPA technology is also used in hospitals and medical facilities around the world, helping keep medical environments clear of bacteria and viruses while providing clean air.

The HEPA filters in use on American’s fleet capture at least 99.97% of airborne microbes by circulating the cabin air once every 2 to 4 minutes. As the filters purify the air on the inside of the aircraft, fresh air enters the engine compressor on the outside. Next, it makes its way into the air conditioning system and is mixed with the recirculated, filtered air. This mixture results in a higher level of humidity in the cabin, providing a more comfortable experience for customers. This mixing process also helps the environment, as mixing fresh air with recirculated air results in a lower overall fuel burn.

For example, on American’s Airbus A320 and Boeing 737 families of aircraft, air is filtered through two HEPA filters located near the forward cargo compartment. On our larger Boeing 787 family of aircraft, air is filtered through three HEPA filters – one located towards the centre of the aircraft’s ceiling and two near the forward cargo compartment. On our largest aircraft, the Boeing 777 family, there are eight HEPA filters – four near the forward cargo compartment and two over each aisle near the middle of the aircraft cabin. Filters are changed regularly to ensure the uninterrupted flow of clean, fresh air into the cabin. American also periodically tests removed filters to ensure they’re meeting performance requirements and we adjust our change intervals if necessary.

American also takes extra steps to ensure customers and team members breathe clean air aboard our aircraft. Over the past several years, American has been further improving our HEPA filters by adding a layer of activated carbon to our filters to provide additional removal of fumes, odours and volatile organic compounds. Today, these carbon HEPA filters are installed on all of American’s A320 and 787 aircraft.

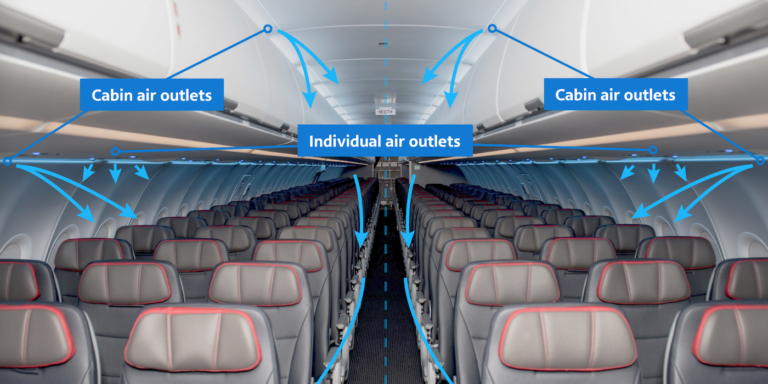

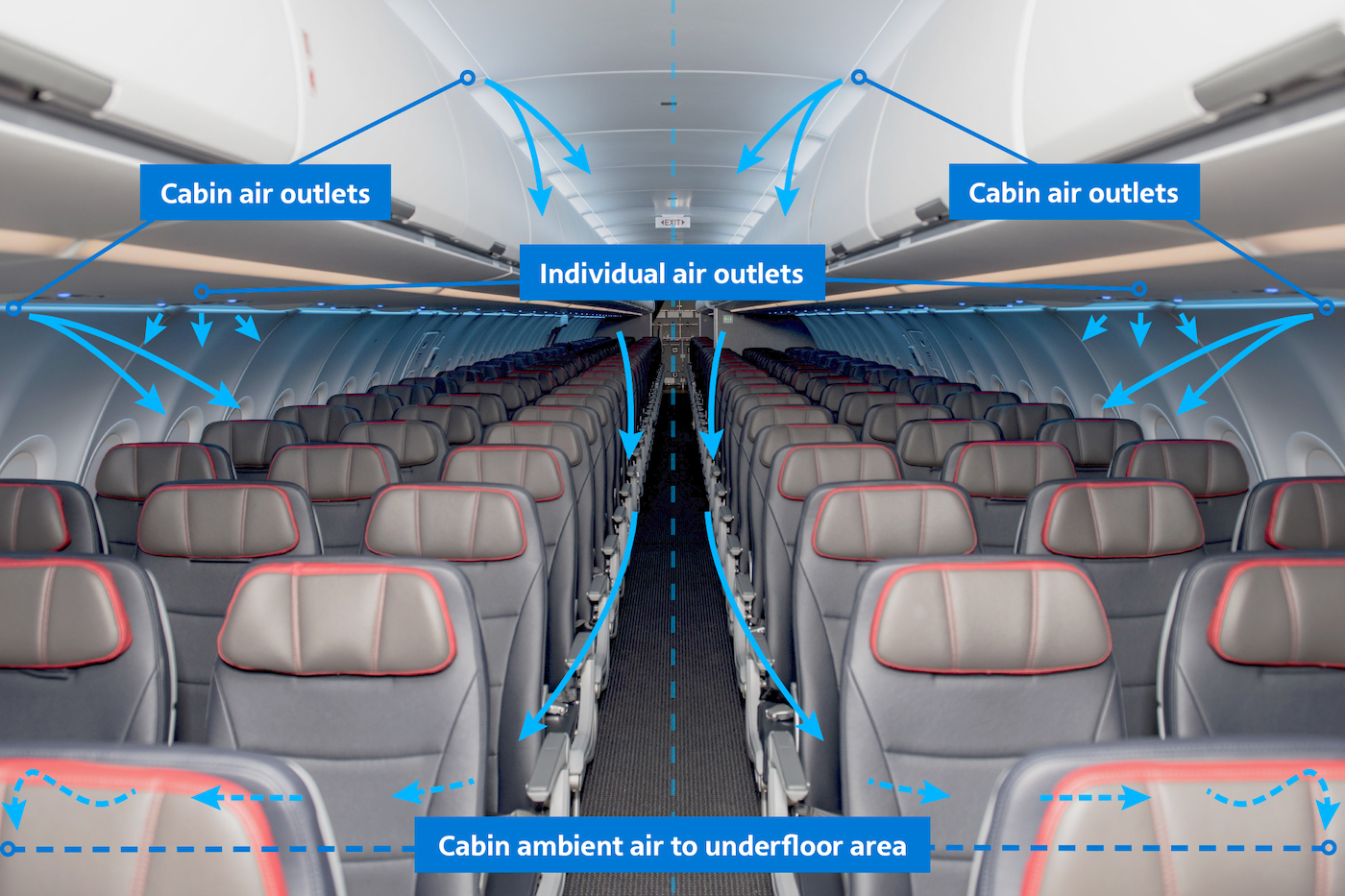

Cabin air is filtered from the top down, so be sure to open the overhead vent to let the filtered airflow on your next flight. As air is pushed downward, it re-enters the filtration system along the walls of the aircraft and repeats the filtration process, mixing outside air with filtered air.

A few filtration FAQs:

Which American Airlines aircraft have HEPA filters?

American’s entire mainline fleet features HEPA filtration. In our American Eagle fleet, the Bombardier CRJ700 and CRJ900 and Embraer E175 aircraft feature HEPA filtration. There currently isn’t a government-approved HEPA solution for the Embraer E140 and E145 aircraft.

What is the smallest particle size that the cabin air filter element can remove?

According to IATA (the International Air Transport Association), air filters can remove very small particles, such as bacteria and viruses. Virtually all viruses and bacteria are removed; even the most difficult particles in the range of 0.1 to 0.3 micron are filtered out with an efficiency level of 99.995%.

Who manufactures HEPA filters for aircraft?

Two companies make HEPA filters for commercial aircraft — Donaldson Company and Pall Aerospace.