While a humdrum trip to the shops or a café involves a dizzying array of choices and personalization options – anyone for a venti non-fat half-caff double-shot frappuccino with a dusting of cinnamon? – the supposedly more complex matter of buying a ticket for air travel is largely a matter of choosing an airline and a class of travel, with a later opportunity to select a seat. But though coffee shops have taken personalization to an almost comical extent, consumers do enjoy the feeling of empowerment that choice gives them, so maybe it’s time for airline travel to get with the times.

While a humdrum trip to the shops or a café involves a dizzying array of choices and personalization options – anyone for a venti non-fat half-caff double-shot frappuccino with a dusting of cinnamon? – the supposedly more complex matter of buying a ticket for air travel is largely a matter of choosing an airline and a class of travel, with a later opportunity to select a seat. But though coffee shops have taken personalization to an almost comical extent, consumers do enjoy the feeling of empowerment that choice gives them, so maybe it’s time for airline travel to get with the times.

Enter Transpose, a modular concept being developed by Airbus’s A3 think-tank in Silicon Valley, which could change the way people behave during a flight and the way they plan their trips – and is being developed with a genuine view to entering production.

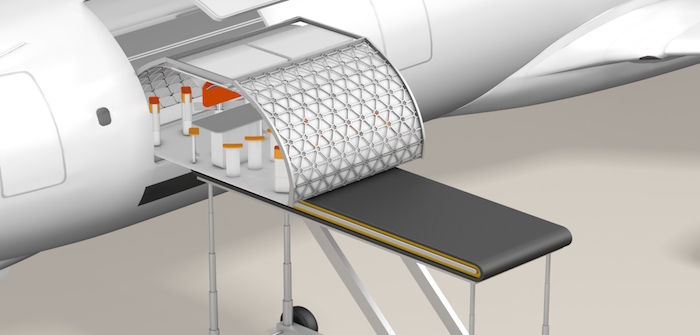

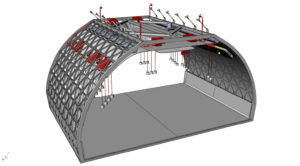

The idea behind the concept has been widely reported already, but as a brief description, the Transpose concept would see freighter aircraft loaded with a series of modular cabins, similar to cargo containers, that are inserted through the standard loading door. Passenger modules could be fitted with anything from high-density economy seating, to suites or even private compartments, while other cabins could contain social zones such as bars, shops or spas, with potential revenue opportunities if companies wish to sponsor cabins to promote their brand. The modules can be swapped in and out to suit routes and times, allowing customers to select a flight with the right features for them, and for airlines to tailor a configuration for specific flight legs: high-density seating for a short hop, for example, and greater comfort and onboard destination options for longer flights.

Keeping it real

The A330-200F is the notional starting point for the project. That the concept is being built around an existing airframe is important to note as it indicates a consideration of reality, and asking Airbus to develop a new airframe to enable Transpose is simply not realistic.

“We’re trying to reuse as many existing designs as possible so that we don’t have to reinvent things like a loading and unloading infrastructure,” explains Jason Chua, project executive for the Transpose project. “We want to leverage existing Airbus product.”

That existing product includes K-loaders that can load and unload an entire wide-body freighter in around 40 minutes, which is key to the team’s aim of being able to switch cabin configurations during a turnaround. From a practical perspective, this would involve having a range of modules at airports around the world – a challenge but not an impossibility. As Chua says, “We think this is theoretically possible, so that’s what we’re shooting for.”

The passenger view

Coffee shops and bars, gyms and spas all sound like great modular experiences, especially if offered as something new for economy class passengers. However, whatever class a Transpose flyer has chosen to travel in, with the aircraft being a freighter there is a big part of the passenger experience missing: the view out the window.

But does Chua consider the lack of passenger windows to be an issue? “On a wide-body aircraft today, only a small percentage of people are actually looking out the windows at any time. Most are looking at their IFE screens, using the wi-fi, taking a nap or having a meal.

“We think that with the advent of a modular cabin, more onboard experiences could be created, for example a restaurant or a gym, and these types of experiences don’t require windows.”

Windows may not be required, but their absence would leave the sidewalls looking rather blank. The solution would be OLED surfaces on the sidewalls, which can display anything from light shows to interactive content, to the view outside, fed by external cameras.

“I think all those things are possible, and cabin designers have become really good at creating perceptions of increased space. There has also been a lot of cool thinking about how you can make services more interactive. Having more surface area to work with could unlock a lot of new possibilities, and that’s one of the areas we’re going to be continuing to test and refine in the project.”

In line with its policy of creating realistic ideas, the A3 team is not trying to reinvent too many aspects of the cabin at once or reinvent for the sake of it, so they are having more conversations with passengers to determine if they would demand feature sidewalls.

Worth the weight

Another major reality check for the project is the team’s consideration of the potential weight penalty of the mounting structure for a modular system compared with a more conventional passenger aircraft setup.

Chua responds, “You can’t get something for nothing, so there will be some modular ‘overhead’ as we call it, in order to gain the increased flexibility and to unlock more possibilities in terms of the experiences that a modular interior provides.”

Aside from a few windows for safety checks, the smooth fuselages of Transpose-equipped freighters will bring some weight and aerodynamic benefits to help offset the potential weight penalty of the modular mounting structure compared with a more conventional passenger aircraft setup.

Of course airlines could also charge passengers an additional fee to access the special modules, creating a new revenue stream to help offset any weight penalty.

However, one of the most interesting ideas in the Transpose concept is the notion that large brands could partner with airlines to create their own branded experience within a module. There could be a Starbucks coffee capsule or a Taco Bell snack cabin, for example, with the revenue gained from the branding partnership offsetting the modular overhead for the airline and (in theory) making it a cost-neutral additional experience for passengers.

“We’re looking at the business case holistically, and we fully believe that the additional revenue that’s possible with a modular interior more than offsets the increased operational costs associated with this modular overhead,” states Chua.

For Transpose, brand partnerships could go even further, as Chua envisages brands taking over entire modules. For example, film studios wanting to promote a new blockbuster movie could fill a module with characters and merchandise, screens showing exclusive content, and people and technologies that passengers could interact with. He sees this possibility as immersive, enjoyable and interesting for passengers, and a great way for studios to market to a captive audience.

“A Transpose module gives brands and advertisers a really rich medium through which to convey their values, and we think that might be a source of additional revenue for airlines that could mitigate the cost that passengers might otherwise bear in terms of the modular overhead,” states Chua. “There are a lot of ways to slice the revenue pie, but notionally speaking, one way in which we are looking to close the business case is to unlock these opportunities for advertisers and brands. They will certainly play a large role in the revenue picture as they provide interesting experiences for passengers.”

The big one: certification

The theory of Transpose is certainly interesting, but the speed of A3’s innovative ideas will be tempered by one of the reasons the aerospace industry takes some time to get ideas off the ground: certification.

How long would it take to get a module off the drawing board, through certification and onto an aircraft? Chua cannot give an estimate at this stage, but states the team is working hard on certification.

“On the regulatory front, we’re engaging with the FAA, and so far we’ve had some good conversations. In terms of manufacturing, a large portion of this project is the creation of a set of rules and guidelines that can be distributed to cabin manufacturers and airlines so that they understand how to create a module.”

An interesting aspect of the design he mentions is that after the general Transpose concept is approved, regardless of how long it might take to manufacture and certify a new type of module, that time is relatively cost-effective because it does not require any aircraft downtime. Being a modular concept, new Transpose cabins could be fitted out and certified off the aircraft.

But then, the order in which modules are fitted would also have to be approved – after all, whether passengers make an emergency egress through a gift shop, seating area or spa is an important consideration. A set of pre-approved configurations could be the solution.

“Our goal is to maximize interchangeability, so we want the aircraft to be as agnostic as possible as to where modules can be fitted. From a technical perspective, we think that there are ways to make Transpose agnostic by creating specific permutations of modules,” concludes Chua.

The A3 team believes that the first demonstration prototype of Transpose could be flying in four years. This sounds rather ambitious, but remember that while A3 may be a Silicon Valley bunch of disrupters, they have the might and expertise of Airbus behind them all the way.