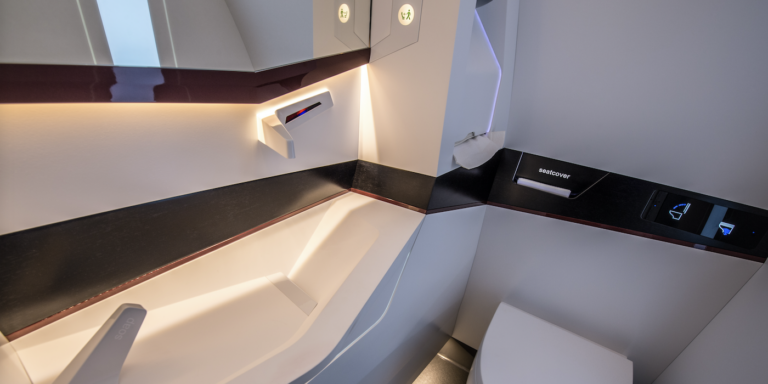

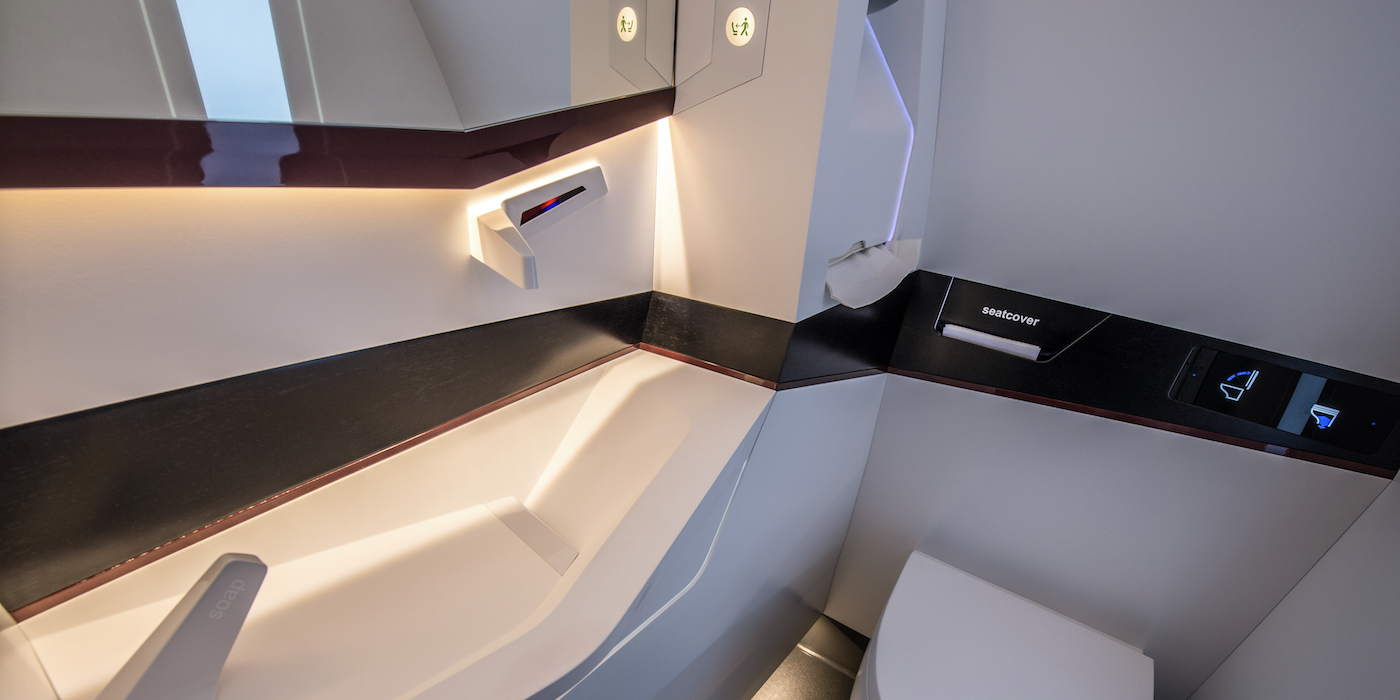

Imagine a transparent, glowing, crystalline interpretation of an aircraft interior. Mood lighting is integrated into surfaces, with the colors adapting to circadian rhythms, while sophisticated acoustics add to the pleasant atmosphere. Imagine the cabin functionalities being simple to use, efficient and economical to run thanks to a standalone energy supply. Imagine all of this, and all of it being centrally controlled and finely tuned to the requirements of crew and passengers. All these ideas have been combined in Diehl’s DIANA research project to create one single vision: the aircraft cabin of tomorrow.

Silvan Fiedler, industrial design manager and director of industrial design projects at Diehl Aircabin, explains the thinking behind the concept to Aircraft Interiors International.

What makes DIANA so fundamentally different from other cabin designs?

Fiedler: “The main distinguishing characteristic of DIANA is how we use geometry, the shapes of components, and lighting. We took some inspiration from the automotive sector, where the use of surfaces as sculptures – for example how they interact with sunlight and the play of light and shadow – has been a decisive feature for some time, in terms of the design of elements.

“One of the most important components for us was the ceiling [pictured above]. Traditional ceiling lighting in aircraft cabins is designed to make the space below it appear bigger than it really is. This large unstructured surface, however, often gives a fairly dull impression. What we wanted to do was to use simple geometry to let the whole cabin appear livelier.”

What made you decide to use organic, crystalline shapes?

Fiedler: “From a functional point of view, plain, straight surfaces are actually not very practical. Convex and concave shapes are better in terms of static and acoustics, as well as weight. This approach echoed a contemporary trend, but we used it in quite a restrained way because we wanted to create a lasting design.”

What unique challenges did this project create?

Fiedler: “We found dealing with lighting, surfaces and shapes rather demanding. It took us a long time to fine-tune the interplay of these elements in the cabin in order to realize the desired effects. There is a thin line between excitement and relaxation.”

What role do colors play? Are they a fixed component of the design or is there room for customization?

Fiedler: “Of course colors are a part of the overall concept. However, the customer does have the option of modifying the parts that the passenger uses, such as handles and control elements, according to their requirements. To enable this, we have a catalog with various colors, surfaces and textures to choose from. This was why we kept the color of the cabin relatively neutral.”

What added value does the new design offer to passengers and airlines?

Fiedler: “First of all it is designed to make flying as comfortable as possible for passengers. It needs to be a cohesive, overall concept, comprising lavatory, galley, and the whole entrance area. Our aim – and this is what design language is all about – is to make the whole interior cabin appear as if it is one single piece.

“The advantages compared to other concepts are obvious. Because OEMs are supplied by a host of different suppliers, in practical terms, it is almost impossible to have a consistent design language. We combine high-value functionalities with an appealing visual appearance, create synergies of technology, and connect cohesiveness with efficiency.”

What is still in development, and what elements can still be improved in the cabin design of the future?

Fiedler: “We are now in the process of aligning our concept to cover the whole entrance area of the cabin. Doors, ceilings, control elements – our ambition is to create the whole area as a continuous product in one style, rather than an assembly of individual elements, as it has been up until now.”

For more Diehl insight, see our interview with Diehl Aerosystems’ CEO CEO Rainer von Borstel HERE, where he explains how the company has increased its global footprint and sales turnover by a factor of five since 2009.

Silvan Fiedler has worked as a designer in the aircraft industry since 2001. In 2008 he became industrial design manager and director of industrial design projects at Diehl Aircabin in Germany. Working with industrial designers, engineers, technicians and other expert specialists, Fiedler is part of the innovation team that has been contributing valuable development work to the DIANA project.