It may seem odd to announce the winners of the 2020 Crystal Cabin Awards in 2021, but then it has been a rather unusual 12 months. As vaccination programmes enable glimmers of a return to normal life, aviation can begin its path to recovery with greater certainty, making 2021 perhaps a more appropriate time to reveal the winners.

In the unlikely event you are unfamiliar with the Crystal Cabin Awards, they are the most highly regarded honours for the aircraft interiors, aviation innovation and engineering, and airline passenger experience sectors. 2020 marked the 14th year of the awards, an independent initiative organised by the Crystal Cabin Award Association in association with the Hamburg Aviation cluster.

Airlines, aerospace suppliers, universities, design houses and aircraft manufacturers from 21 countries submitted some 105 entries for consideration in the 2020 shortlist, with an initial evaluation process between the 27 members of the expert international judging panel (see below) reducing the list to 24 finalists. In February 2021 the panel met again – online rather than the usual coffee and pastry-fuelled sessions in Hamburg – to dig deeper into the entries with the finalists and decide which eight innovations deserve the coveted trophies.

Given travel and social restrictions, the traditional glamorous awards ceremony has also been switched to an online event this year. We can still get into the spirit of the ceremony though, so pour a glass of your preferred beverage and recline as we announce the worthy winners of the 2020 Crystal Cabin Awards…

Cabin Concepts

The Cabin Concepts category always receives the most public and media interest, and the 2020 results should continue this trend. This category recognises complete cabins, and the contenders are typically airlines, aircraft manufacturers and design companies – or a combination thereof. Airbus took the prize in 2019 for its ‘Lower Deck Pax Experience’ modules, with Emirates’ Boeing 777-300ER first class suites and Safran’s Essential business class seat taking the runner-up positions. The 2020 winner is something a little different…

WINNER: Eviation Alice

The 2019 Paris Air Show saw the launch of Alice, an all-electric, zero-emission regional aircraft from Eviation. The electric propulsion helps ensure that passengers will enjoy low noise and vibration during flight, as well as the practical benefits of a range of 650 miles at a 240-knot cruise speed. But what other passenger experiences await within the all-composite fuselage?

In compliance with FAA FAR 23 for commuter and on-demand operations, the aircraft has capacity for nine passengers and two crew members. The prototype cabin interior was designed, developed and built with Lisbon-based design consultancy, Almadesign, with the aim of creating a brand new passenger experience for the zero-emissions commuter aircraft.

The interior has an asymmetric reverse herringbone seating arrangement, with four seats port-side and five starboard. During boarding the seats are aligned with the direction of flight, but after take-off they can be rotated towards the window, enhancing passenger privacy, headspace – and the view. In-seat comforts include a large side console, storage space for small items, and a charging point.

Almadesign developed a modular system for the interior parts and their assembly, which the studio says will enable a high-end aesthetic to be created using feasible production processes. The interior is also lightweight, with composite materials and aluminium structures specified, enhanced through elements such as polished aluminium brand logos on high-gloss surfaces.

RUNNERS UP:

Virgin Atlantic: Upper Class Loft

The Loft is the latest iteration of Virgin Atlantic’s on-board social space, launched in 2019 on Red Velvet, the airline’s first A350-1000. While the lounge is for the use of Upper Class passengers, the airline has long seen benefits from having all passengers enter a vibrant social space upon boarding at Door 2, as it creates a ‘brand handshake’ and creates a positive sentiment of the passenger experience, even for those heading toward the rear of the aircraft.

A bar has long been a key part of Virgin’s Upper Class cabin experience, but customer feedback indicated that Virgin Atlantic’s top-tier flyers would now prefer a lounge zone that maximises space for customer use, and indeed a space that can be used throughout the flight for many uses, whether socialising, watching the widescreen TV with a Bluetooth headset, having a work meeting, or simply enjoying a change of scenery.

The Loft is the result of a design collaboration between the airline and Factorydesign, as well as AIM Altitude and other partners. After considering the aims of the space and its planned location, Factorydesign decided the best approach was to manipulate the available space at either side of the doorway to create sufficient room for a versatile seating arrangement that can accommodate up to eight people – five seated and three standing. The space also serves as a cross-aisle, making the Loft an efficient use of a typically underutilised area during flight, as well as a luxurious and sociable space.

Various seating orientations are possible for passengers in The Loft, including facing each other in booth seats, facing the neighbouring banquette with a table between for subtle separation, or the casual end bay seat facing the doorway. All the seats feature safety belts, which enables customers to enjoy the Loft for more of their inflight experience, even during turbulence.

The sense of a flow into the Upper Class cabin is enhanced by the use of semi-translucent privacy panels which give a ‘glimpse’ either way into the spaces, softening the visual barrier between them.

If you want to know more about the Loft design, we take a deep dive HERE.

Boeing: 777X Sky Architecture

2020 marked the 25th anniversary of the launch of the Boeing 777, and its spacious cabins have been enjoyed by so many travellers over that quarter-century: indeed the triple-seven is the world’s best-selling wide-body airliner. The cabins have received updates over the years, but for the 777X, Boeing has worked with Teague to take the architecture to the next level.

Every inch matters in the cabin, and the teams worked to add 4in to its internal width, carved out to 235in (597 cm) through the use of thinner cabin walls and space-efficient insulation. Indeed those four inches will enable airlines to specify a 10-abreast layout in economy, with 18in-wide seats, all within the same external fuselage cross-section as the X’s predecessor.

The cabin design is an application of Boeing’s Sky Interior philosophy, a holistic approach that brings together every aspect of the cabin, with visual aspects such as the architecture, lighting, stowages, ceilings and sidewalls working in harmony with advanced technologies introduced with the Dreamliner. These technologies include systems that enable a cabin altitude of 6,000ft, advanced cabin air filtration and humidity systems, and Smooth Ride Technology.

The cabin of the 777X is impressive in its engineering, and also for its styling potential. The simple lines and white finishes of the Sky Interior serve as a blank canvas for airline customers to express their brand, with many customisation options being quick and simple to achieve.

For more details of the B777X cabin, see our exclusive feature HERE.

Greener Cabin, Health, Safety & Environment

While passenger comfort and airline efficiency are major focuses of the awards, there is another very important consideration: environmental and health factors. This category recognises the benefits of innovations that either reduce the negative effects of aviation on the environment, or minimise health or safety hazards and security problems for passengers, staff or live cargo.

WINNER: Diehl, Greywater Reuse Unit

Passengers are likely to be washing their hands more thoroughly during post-Covid flights, increasing demand for water on board. However, water is a heavy resource to carry on an aircraft. With Diehl’s Greywater Reuse System, the water used in the lavatory sink for handwashing (grey water) is reused for flushing the toilet, which is more efficient than using precious potable water.

According to Diehl this process reduces the amount of potable water typically used on a Boeing 787 Dreamliner flight by 250kg, resulting in CO2 savings of around 550 tons per year and per aircraft, as well as creating substantial financial savings for the operator. Despite this significant saving in the use of potable water, twice as much water will be available for flushing the toilet compared to some of today’s systems.

The Greywater Reuse System treats the handwash water to prevent any resulting undesired odours, microbial regrowth, unpleasant appearance and health risks. Optimised spray nozzles aid toilet cleaning, while the automated toilet lid minimises the need to touch high-contact areas.

RUNNERS UP

ATR: AudioBack

According to 2018 World Health Organisation figures, 6.1% of the world’s population suffers from a hearing loss that qualifies as a disability, and that figure is set to double by 2050. Today, hard-of-hearing passengers face a number of issues when travelling by air, as their disability prevents them from clearly distinguishing inflight announcements, resulting in anxiety and a feeling of exclusion. And the wearing of face masks on board has not helped matters.

ATR, the regional aircraft manufacturer, and Bacqueyrisses (the entry’s patent owner), contended in this category with AudioBack, the first standalone hearing-aid loop for use in commercial aviation.

AudioBack is designed to capture any cabin and flight crew audio inputs, and send them to the passengers’ hearing aids set up in Telecoil (T) mode, via a magnetic field signal. AudioBack sends a clear and pure sound directly into the traveller’s hearing aid, thereby enhancing safety and creating a more inclusive cabin environment.

PriestmanGoode: Zero economy meal tray

The Zero economy meal tray is a concept product created by transport design consultancy, PriestmanGoode, which aims to reduce the amount of weight required for the meal service on passenger flights, and the amount of plastic waste generated . The solution is a lightweight tray with each element made of edible, biodegradable and/or commercially compostable materials.

In its bid to reduce the vast amounts of single-use plastic that come with meal deliveries, PriestmanGoode has explored a vast range of food-safe materials that have been developed for the catering industry, from cups made from coffee grounds, to algae, bamboo and rice husk.

The concept design (more details HERE) aims to encourage suppliers and airlines to rethink the meal service in a more eco-friendly manner, particularly ahead of legislation to ban single-use plastics, which in some countries is proposed for as early as 2021.

You can watch a video explaining the finalists in this category HERE.

Materials & Components

Developing new materials, material applications or a new combination of materials for cabin systems can cut production costs and maximise usability. This category rewards such innovation and embraces an enormous variety of different aircraft components. Entries can be an innovative, single technical component or material, but not a fully developed product such as a seat.

WINNER: e₂ip Technologies, In-Mold Electronics

As people grow accustomed to using smart surfaces on electronic devices and in automotive cockpits, it is a good time to introduce these elegant, user-friendly surfaces into the cabin space. e₂ip Technologies has seized this opportunity, developing IME, a design that integrates electronics within the moulds of controllers. With a simple hand gesture such as a swipe, the smart surface of the controller comes to life, revealing clearly backlit controls, including capacitive on/off switches, sliders and dials for volume or light levelling, and more.

Smart surfaces are key to IME (In-Mold Electronics), which e₂ip sees as the future of HMI. The company, with the support of the National Research Council of Canada (NRC), has advanced the materials and processes used in IME to enable greater design freedom. This freedom flows from ideation, to fabrication from the industrial designer’s imagination, to the airline passengers’ fingertips.

RUNNERS UP

Schott: Jade reading light

Style, quality and usability come together in Schott’s Jade reading light, the first aviation light to be made from glass. The light was designed with PriestmanGoode (the studio which created the Zero eco-friendly meal tray above), with an integrated ambient light halo featuring a sleek, full glass cover that is as intuitive to use as a smartphone. Jade features capacitive touch technology, which means that passenger can ‘swipe’ the surface (among other gestures) to adjust the focus and brightness and create their own illumination experience.

The homogeneous tempered safety glass cover is robust, scratch-resistant and shatterproof, and does away with technical components such as joints, arms and angles. Instead of relying on bulky optical lenses for light transport, this product powers thin fibre-optic light guides with white LEDs, and thanks to the spatial separation of LED and light guides as well as the flexibility of fibre optics, Jade has a mere 0.5in installation depth, allowing for seamless integration into a seat and easy front installation and deinstallation.

Available in landscape and portrait format, the light can be printed with any décor, such as standard or metallic RAL colours, to imitations of stone, fabric or ornaments, or even 3D effects. Jade can also be certified for all relevant aviation and OEM requirements.

Diehl Aerospace: Experience Line Bridge

Diehl Aerospace enjoyed another finalist place in the awards with a fully integrated system that combines cabin lining elements and surfaces, image projection and cabin lighting to create an enhanced inflight experience.

A plethora of optical effects can be created through the combination of several illumination technologies. These technologies can include cabin illumination via accent lights, projection systems and displays. Diehl’s Experience Line Bridge combines and controls all such technologies, enabling designers to create those ‘wow’ effects they all want in the cabin. The Experience line Bridge can be integrated in any aircraft cabin, whether discrete or bus controlled, and it adapts to existing control or cabin management systems, with no additional training needed for its use by cabin crew. A prototype of the system has been flying since August 2019.

You can watch a video explaining the finalists in this category HERE.

Passenger Comfort Hardware

This category recognises innovative hardware ideas that enhance passenger comfort, from seats, lavatories and bins, to partitions, lighting systems, linings and VIP products.

WINNER: Safran Seats, Modulair

Most airlines strive to offer the best flying experience in economy class, but adding comfort can sometimes also add weight and complexity, while not addressing the individual preferences of a wide range of travellers.

In response Safran has developed Modulair S, a set of seating comfort modules that can enhance the inflight experience for a broad range of passengers, whether child or retiree, solo or family traveller, and whether they wish privacy, sleep or entertainment during their journey.

Safran Seats worked with the French design school, ENSCi (L’École Nationale Supérieure de Création Industrielle), to develop the Modulair’s key features, which include the ‘U-dream’ headrest (a flexible design with adjustable privacy and support), armrests that give the middle seat a little more space, a double-deck seatback table that can be adjusted for different needs during flight, 3d-knitted amenity pockets, and flexible stowage for devices.

Runners up:

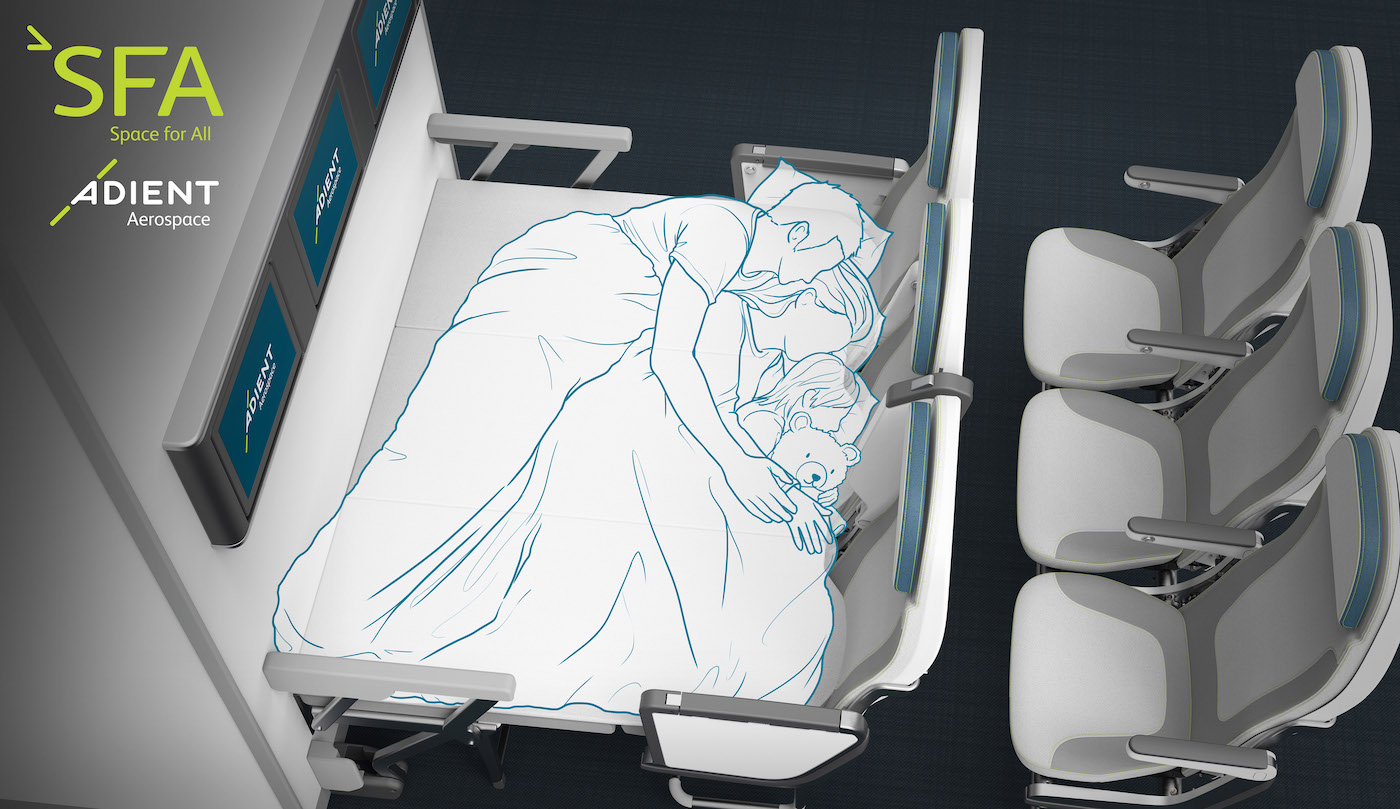

Adient Aerospace: Space For All (SFA)

Bulkhead seats are preferred by many travellers as they can offer extra legroom as well as bassinets for babies. The Space For All ‘SFA’ concept from aircraft seating company, Adient Aerospace, enhances the front row seat experience with a mechanism that extends out from the lower bulkhead wall. When locked in position, SFA provides each passenger with an extended flat surface for use as a lounge seat or, with all three surfaces deployed in a triple seat, it creates a shared flat space – perhaps for sleeping or for parents to entertain their children.

The concept can be retrofitted onto existing aircraft fleets, but is further optimised with the Adient Aerospace front-row triple seat, which incorporates a patent-pending folding centre armrest with bi-fold meal table. With the seat armrests in the raised position, SFA provides the front-row passengers with more than 17 sq ft of shared flat bed space. In bed mode, the centre armrest can be lowered and deployed, to provide a coffee table or work station.

Ciara Crawford: Row 1 airport wheelchair system

All passengers should have an enjoyable and dignified flight experience, but for some travellers with disabilities, this is still not the case. At the moment there is a perceived lack of focus on the accessibility of aircraft or aircraft seats for people with reduced mobility (PRMs). Many aircraft seat designers are focused on making seats smaller with a tighter pitch in order to maximise cabin seating capacity, but this can reduce the amount of independence and freedom available for PRMs. This issue inspired Ireland-based product designer, Ciara Crawford, to create the Row 1 airport wheelchair system for aircraft accessibility. Crawford has experience working as a concept developer for an aircraft company.

The Row 1 airport wheelchair system allows the passenger to use one seat for the whole journey, taking them all the way from the check-in desk to their destination airport and cutting down the number of seat transfers required. The seat is then parked onto and strapped into an existing aircraft seat to allow for quick and easy boarding and disembarking. The process is quick and simple, eliminating the concerns that many disabled passengers have of being watched while boarding, especially when being lifted by crew members into their seats – the latter being a particularly important factor to eliminate.

The chair design has been simplified as much as possible, with adjustable handles and armrests, and wheels for easy manoeuvring. The design also features an automatic steering system that is controlled by the user, enabling PRMs to make their own way through the airport.

You can find more details HERE.

You can watch a video explaining the finalists in this category HERE.

Visionary Concepts

The Visionary Concepts category is an exciting prize which looks to the aircraft cabins of tomorrow. So what experiences could we be enjoying in the coming years?

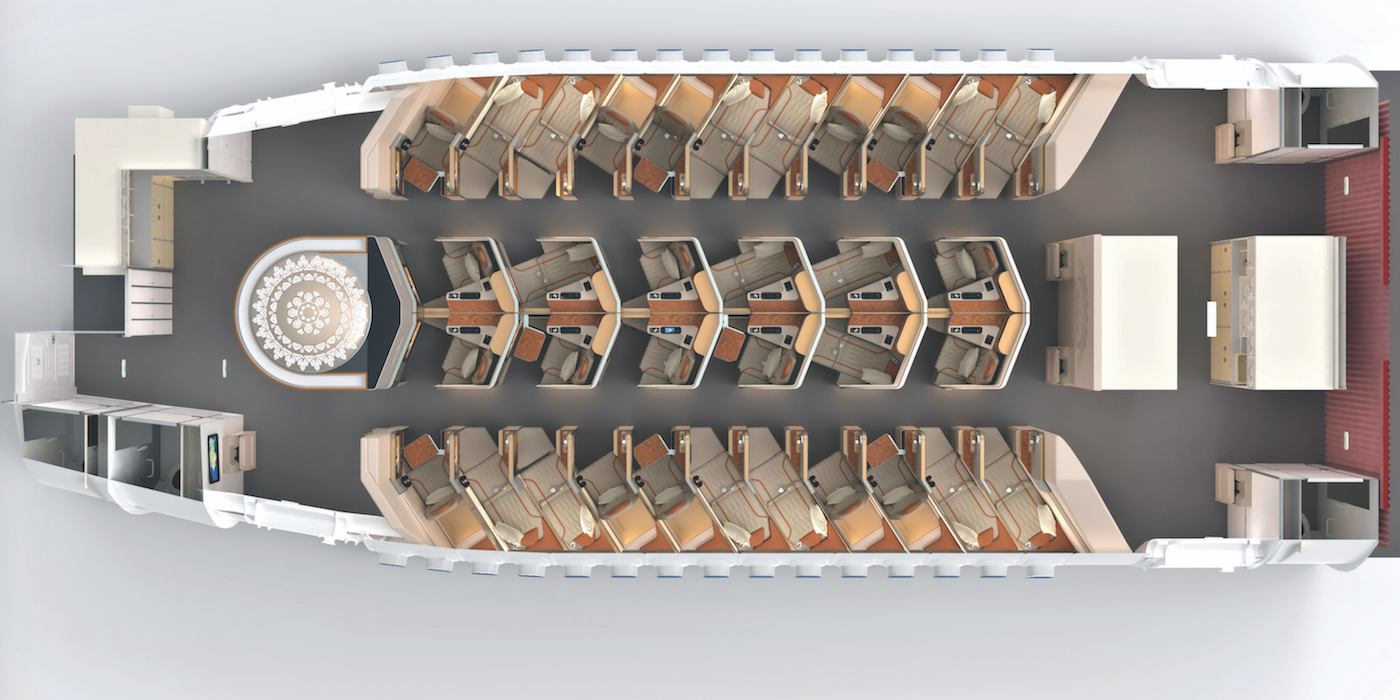

WINNER: Airbus Airspace Cabin Vision 2030

Inspired by airlines, technology companies from Silicon Valley and start-ups, Airbus has brought to life a future flying experience – the Airspace Cabin Vision 2030. The vision is of cabin layouts boasting more flexible seating and sleeping configurations, as well as inflight lounges with transforming modules. The Airbus design would give passengers more choice and flexibility, enabling them to select a personalised flight experience based on their individual needs, whether they are travelling for business or leisure, alone or with family. Crews would work in a digitally enabled environment, allowing for more efficient operations and more time spent with passengers.

Unique cabin ambiences will be created through the use of surface lighting, OLED screens and artificial outside views, as well as individual ambience settings for the in-seat space. Everything would be as seamlessly connected as it is on the ground, bringing the Internet of Things (IoT) into the cabin and enabling Big Data services.

RUNNERS UP

AIM Altitude: Arca Galley System

The Arca Galley System is a meal-service innovation, created with sustainability and the efficient use of cabin space in mind. Designed by AIM Altitude, Arca reformats the aircraft galley to make optimal use of the area, with the space required for onboard meal stowage reduced by using meal packs instead of trays. Arca embraces the trends towards introducing alternative service models, customised meals and more sustainable practices. By eliminating the tray and consequently the need for full-depth carts, ARCA revolutionises the possibilities for the galley in the first real shake-up of this area of the last 60 years.

With Arca, meals are stored in aesthetically pleasing full-height fridges. Boxed in sets of 16, the meals can be easily moved to a reusable folding cart for meal service. Repurposed into waste containers, the carrier boxes can be used for recycling collection and separated compacting, enabling zero-landfill flights. The galley area and even the boxes themselves are fully customisable.

The space savings achieved are the equivalent to the cabin footprint of a destination monument or an extra row of seating.

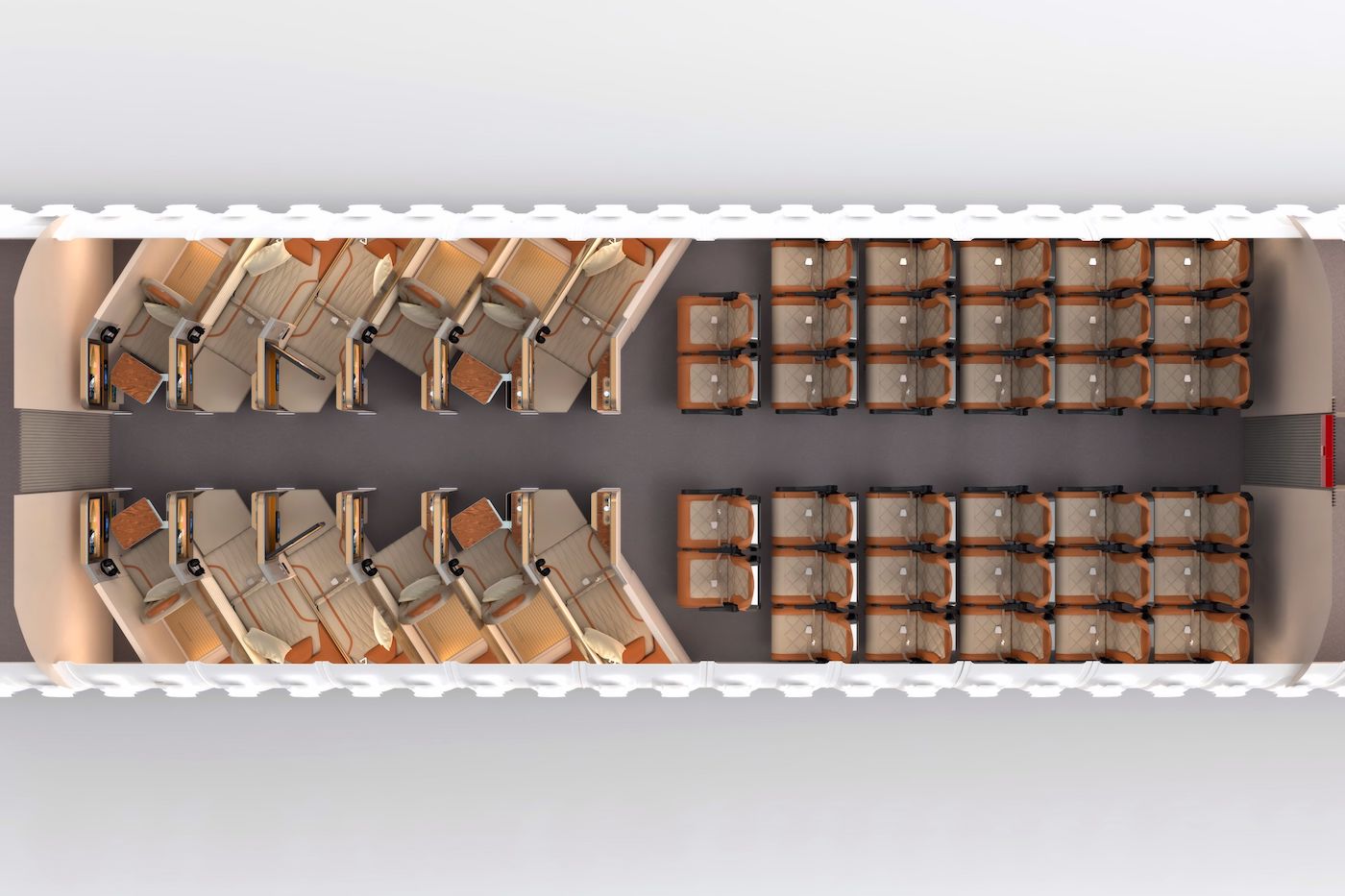

AirGo Design: Galaxy

Galaxy is a space-efficient seating arrangement that replaces the recliners typically found on narrow-body aircraft, with flatbeds. The configuration does not reduce seat count compared with today’s typical layouts, and with a minimum seat pitch of only 27.6in, the Galaxy design enables long-range single-aisle aircraft such as the A321 to achieve their full revenue potential for airlines.

The Galaxy cabin has some seats targeted at family travellers and couples, with a shared wall that can be lowered via a two-way authentication integrated into the IFE system. A passenger can send a request to the neighbouring seat to lower the wall, and they have the option to refuse temporarily or for the duration of the flight. If and when the neighbour accepts, they have the choice of lowering only the top portion of the wall, or the whole dividing panel. Lowering the wall completely would essentially convert the adjacent seats into a queen bed for couples, or even a larger shared area for families with children.

Galaxy is highly modular, and AirGo has also developed a unique seating arrangement for wide-body aircraft. On a Boeing 777 for example, the layout would offer eight more seats as compared to the densest LOPA that is in operation today (United’s Polaris business class).

Galaxy achieves this impressive level of density by using every inch of available space on the aircraft. In many current seating arrangements, the tapered shape of the fuselage creates wasted space as the aisle is generally wider at the front and becomes quite narrow at the back of zone A. By using a careful placement of seats, Galaxy avoids the tapered part of the cabin altogether.

You can read more details of the Airgo Galaxy layout HERE.

You can watch a video explaining the finalists in this category HERE.

In-flight Entertainment and Connectivity

This category covers the fastest growing, fastest developing sector of the aviation industry and includes areas such as accessible content, antennas, passenger apps, moving maps, unique cabin wi-fi features, etc.

WINNER: Safran Passenger Solutions, RAVE Bluetooth Audio

Safran Passenger Solutions has cracked the code for Bluetooth Audio congestion during flight, enabling the entire aircraft to be connected at the same time. Up until now, most commercially available Bluetooth systems did not enable a large number of Bluetooth headphones, in close proximity to each other, to be used at the same time without slowing down the cabin wi-fi. The engineers at Safran Passenger Solutions created a way to control power, antenna direction and protocol to allow each passenger or seat of an aircraft to be connected to Bluetooth audio without impacting the connection quality for other passengers.

Frank Rogozienski / CAPA Pictures / Safran

In addition, passengers are not limited to the headsets provided by airlines. Flyers can connect using their own devices, if they prefer, increasing passenger satisfaction and decreasing costs for airlines.

RUNNERS UP

JetBlue Airways: Multi-Screen Experience

In 2000, JetBlue disrupted the entire commercial aviation industry when it became the first-ever airline with seatback IFE screens at every seat. Two decades later, those seatback screens – with live TV, a map channel, six movies, and SiriusXM – have become engrained as JetBlue’s foundational pillar for the next generation of IFEC offerings. Today, the world we live in revolves around screens. To be ‘connected’ means living at the intersection of productivity and entertainment at all times.

The multiple screens we own and interact with throughout the day don’t serve a single function – we work, watch, listen, play, and communicate, often simultaneously. This activity has been coined as the Multi-Screen Experience, and it’s at the core of JetBlue’s IFEC vision, created with a little help from Thales Avionics, Spafax, Viasat and Astronics. As the airline says, ‘welcome to your living room at 36,000 feet’.

Spafax: Spafax IQ

An industry-first product, the SpafaxIQ IFEC data analytics platform provides airlines with insights on inflight content engagement to deliver better customer experiences. This tool gives an overall view of an airline’s passenger engagement across all IFE systems, supplying cost-per-view data at the most granular level: cabin, route, category, navigation path and language.

The platform, which has launched with Air Canada, delivers four dashboards across movie and TV content and contains over 30 data visualisations that provide in-depth insights into IFE content consumption, enabling Air Canada to deliver an enhanced IFE experience.

Benefits of SpafaxIQ include improved content targeting, improvements in navigation and payment UX for IFE, GUI and portals, identification of monetisation opportunities, increased value of media and advertising partnerships, and identification of cost savings on licence fees and new deal opportunities.

You can watch a video explaining the finalists in this category HERE.

Cabin Systems

The Cabin Systems category considers innovative systems that can make inflight operations more efficient or effective. Category contenders typically include hardware such as galleys, lavatories, trolleys, air conditioning, electrical systems, electronic cabin management systems, waste & potable water systems, and acoustics.

WINNER: Safran Cabin, Sophy smart trolley system

The smart Sophy galley cart system offers more capabilities than just tracking a trolley’s status and performance, even though such technology is still considered advanced. Safran has developed Sophy to provide airlines with a ‘helicopter view’ of a trolley’s day-to-day operations, offering insights on main processes and the milestones of the trolley’s journey during handovers, cleaning, maintenance, in-flight service rounds and more.

The slimline Sophy hardware can fit within any galley cart to collect, share and communicate accurate data with other Sophy-activated equipment in real-time through a ‘mesh network’ , unlocking valuable insights for airline operators. The insights of a trolley equipped with Sophy can save catering costs by helping operators prevent and minimise the inefficiencies caused by mishandling, misplacement or misinformation. No longer will a trolley be left behind during a turnaround or at the catering facility.

Sophy is easy to integrate within existing and new trolley fleets, and is designed to operate in demanding conditions. The device is watertight and temperature resistant, and complies with worldwide regulations

RUNNERS UP

SFS and Jetlite: Lite2fix

Lite2fix is an interface-reduced fastening cover designed to add value to the cabin manufacturer, the airline and the passenger, as it simplifies assembly methods through automation, enables the display of passenger information, and increases well-being through the use of human-centric lighting.

For cabin hardware manufacturers, Lite2fix simplifies the line-feeding process as well as the levelling and processing of the robot, and saves time-consuming steps through its bracketless design, self-adjusting interfaces, automated assembly and multi-ATA functionality. Airlines benefit, as any desired information can be displayed on the LED panels. For example, indicators can help passengers locate free space in the overhead stowage bins and speed-up boarding, seating displays can help passengers find their seats, and there are opportunities to help airlines strengthen their image through cabin branding. For the passenger, Lite2fix provides individual information about their own passenger journey.

SITAONAIR: Next Gen Connectivity Mobile ONAIR 4G

The global aircraft fleet is set to double over the next 20 years, with passenger numbers reaching 7.2 billion. With each passenger carrying more devices – including smartphones, tablets and wearables – and the rates of data consumption becoming more demanding than ever, the thirst for capacity will put a major strain on existing cabin connectivity networks.

That’s why SITAONAIR is in the process of developing its enhanced Mobile ONAIR product, enriched with 4G connectivity, which is intended to lay the groundwork for airlines to implement the next generation of inflight mobile connectivity services.

Mobile ONAIR is SITAONAIR’s next-generation airborne mobile connectivity innovation with 3G and 4G capability. It enables the creation of multi-cellular networks on board aircraft, and allows for the creation of a flexible inflight connectivity experience based on existing 3G and 4G technology, while laying the groundwork for 5G capabilities in the air.

You can watch a video explaining the finalists in this category HERE.

University

This category is a fantastic opportunity for college and university students to present their visions for innovative aircraft interior products and concepts. Ideas should reflect the idea of making flying more comfortable or ecologically friendly. As well as potentially having their ideas recognised by aerospace experts, students in this category may benefit from gaining important contacts within the industry who can help develop their future career.

WINNER: University of Cincinnati, Coffee House Cabin

An interesting proposition is the Coffee House Cabin concept, which instead of the usual layout of travel classes fitted in decreasing order or fare along the length of a twin-aisle aircraft, puts premium economy in the centre of the economy cabin. This is no standard premium economy though, with central desk-style tables rotated 90° running along the centre of the economy cabin. The design was conceived by students and faculty at the University of Cincinnati, Boeing, and the Live Well Collaborative, a multidisciplinary design offshoot of the university.

Workaholics can set up office at the large desks, with ample space for laptops and paperwork, complemented by charging ports. The work stations feature two double-sided retractable high-resolution screens for IFE, messages and inflight services, which also provide a physical partition from the passenger seated opposite. If co-workers are travelling together, a ‘quad’ could be booked in the Coffee House so that employees can communicate with one another during flight.

Of course, the angle of the seats would create issues for taxi, takeoff and landing, so they are forward-facing during those flight phases, with the table wings folded down and secured. During the cruise phase, crew slide and rotate the seats toward the tables to create the Coffee House Cabin.

RUNNERS UP:

Delft University of Technology: Collapsible beds for the Flying V

The Flying V, a V-shaped wing body aircraft concept that is currently under development by Delft University of Technology (TU Delft) in association with KLM, has a cabin in the wing that is oval-shaped in cross-section. The university has developed collapsible beds for the economy class cabin that effectively use the oval cabin space at the rear side of the wing. This configuration is optimised to work with the structural body enforcements and make it possible for three passengers to lay down horizontally.

By allowing the middle bed to slide up, and half of the bottom bed to fold down, this triple-height bunk bed can easily be converted into three seats for take-off and landing, which is a requirement for quick evacuation.

To provide ultimate bed comfort, the bunks include a built-in infotainment system, overhead display, charging points for personal electronics, a tray table and an inflatable backrest to allow for a more upright sitting position whilst in the bunk.

You can read more detail about the Flying V concept aircraft HERE.

The University of Applied Sciences Hamburg (HAW): Isofix

Today’s hardware that enables airlines to provide safe seating for babies and infants during flight can lack comfort, while solutions such as extended loop belts or inflatable cushions are mostly not suitable for infants under the age of nine months. A team at The University of Applied Sciences Hamburg (HAW) has come up with the idea of Isotravel, a system that would enable any child restraint system with integrated ISOFIX connectors to be attached to the passenger seat via the existing seat belt.

The adapter can be quickly attached to the passenger seat by simply looping the seat belt through it – a process that does not require cabin crew assistance or special tools. Users or crew can check that the adapter is securely fastened, either visually or by an acoustic signal. The lightweight and compact design of Isotravel means it can be carried within a passenger’s cabin luggage.

HAW has teamed up with CI Composite Impulse GmbH & Co. and TÜV Rheinland Kraftfahrt GmbH as development and certification strategy partners, to help ensure the design complies with all relevant safety and certification specifications for use in commercial aviation. The team is ambitious, and has also worked out an efficient, cost-effective design and manufacturing process in order to achieve high-volume production for Isotravel.

You can watch a video explaining the finalists in this category HERE.

How the Crystal Cabin Awards work

The Crystal Cabin Award, an initiative of the Hamburg Aviation cluster, is presented in eight categories: Cabin Concepts, Cabin Systems, In-flight Entertainment and Connectivity, Greener Cabin, Health, Safety and Environment, Material & Components, Passenger Comfort Hardware, University and Visionary Concepts. For each category, the 27 expert members of the jury select three finalists.

Airlines, aerospace suppliers, universities, design houses and aircraft manufacturers from 21 countries submitted some 105 entries for consideration in the 2020 shortlist. An initial evaluation process was carried out between the 27 members of the expert international judging panel (see below), following which the list was reduced to 24 finalists. In February 2021 the panel met again – online rather than the usual sessions in Hamburg where the panel tries out designs and prototypes – to interview the finalists to find out more details and decide which eight innovations would win the coveted trophies.

The judging panel:

The judging panel is made up of 27 aircraft cabin experts from around the world. Note: in the event that an entry relates to the commercial interests of a jury member, that member has to abstain from voting in the relevant category.

Adam Gavine. Editor

Aircraft Interiors International

Yung Han Ng. Vice president of product innovation

Singapore Airlines

Peter Cooke. Design manager, aircraft cabins

British Airways

Melissa Raudebaugh. General manager – aircraft experience

Delta Air Lines

Jeff Roberts. Director, cabin & features product strategy & future airplane development

Boeing Commercial Airplanes

Paul Estoppey. Senior director, head of cabin product management

Lufthansa Group

Corinne Streichert. Senior manager, inflight entertainment & connectivity (IFEC) & marketing

United Airlines

Paul Sweeney. Program manager, aircraft design & projects

Qantas Airways

Bernhard Randerath. Vice president of design, engineering and innovation

Etihad Aviation Group

Ingo Wuggetzer. Vice president, cabin marketing

Airbus Operations GmbH

Michael Kaye. Vice president, technical operations

Austrian Airlines AG

Dr Joe Leader. CEO

APEX / IFSA

Zuzana Hrnkova. Vice president of marketing

ATR

Nicolas Pinel. Senior advisor to the CEO

Acro Seating

Rolf Dieter Sellge. VP S&M – Super98LLC

Aviation consultant

Bridget Sheriff. Vice president, interiors engineering & technology

Collins Aerospace

Vern Alg

Independent consultant in aircraft interiors project management

Walé Adepoju

Entrepreneur and business consultant

Peter Bishop. Managing director

Bishop GmbH

Prof Peter Vink. Professor at the faculty of Industrial Design Engineering

Delft University of Technology

Dr Holger Friehmelt. Head of Institute – Institute of Aviation

FH Joanneum Graz (University of Applied Sciences), Austria

Marisa Garcia. Founder

Flight Chic

Prof Werner Granzeier. Professor Emeritus

Hamburg University of Applied Sciences (HAW Hamburg)

Dr Dierk Hickmann. CEO Engineering

Office Dierk Hickmann

Mary Kirby. Founder, editor and publisher

Runway Girl Network

Wolf-Dieter Kuhnla. Vice president, R&T and innovation

Diehl Aerosystems

MORE TO COME IN 2021

2021 will see a further Crystal Cabin Award ceremony, as this year, the jury will also award two special categories ‘Clean & Safe Air Travel’ and the ‘Judges’ Choice Award’., in recognition of the industry’s response to the challenges of Covid-19. The second awards ceremony is scheduled to take place at Aircraft Interiors Expo in Hamburg on 31 August, 2021.

Industry support for the Crystal Cabin Awards

Several sponsors and media partners support the Crystal Cabin Award: Aircraft Interiors International magazine, Airbus, Boeing, Aircraft Interiors Expo (Reed Exhibitions), APEX, Future Travel Experience, Boltaron, Diehl Aviation, Jetliner Cabins, Sekisui SPI, TSI Seats, AIME 2020 (Aircraft Interiors Middle East), Ameco Beijing, Bluebox Aviation Systems, Burrana, Collins Aerospace, Ferchau Aviation, Fit AG, Flightchic, Flightglobal, Hamburg Invest, Handelskammer Hamburg, Jetlite, Lufthansa Technik, Panasonic, RedCabin, Runway Girl Network, Vartan Aviation Group and The World of Aviation.