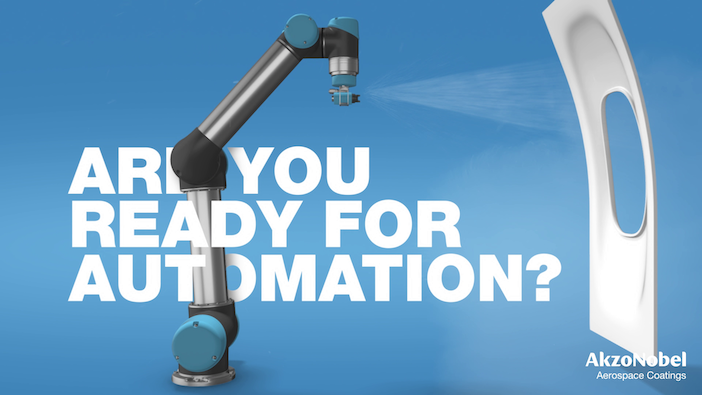

Aircraft manufacturers are increasingly adopting automated processes for high-volume production line performance, including the coating of cabin interiors. In response, scientists at AkzoNobel Aerospace Coatings have been developing a new 1K formula for aircraft interior coatings, which they claim can be used for both automated and manual processes, while maintaining the same level of consistency and performance of today’s coatings.

According to AkzoNobel, creating ready-to-use coatings for manual, robotic and automated lines allows for higher-speed application – beneficial when high volumes of cabin products are being manufactured. The company also says the 1K formula enables a more efficient coating operation, as customers can cover more surface using less product, while also gaining energy efficiencies.

Trials of the new coatings products are being supported by selected members of AkzoNobel’s technical services teams, all of whom are qualified painters with decades of experience, so they can give practical and technical advice on maximising the benefits of this innovation.

“Whereas the skills of the individual will always be in demand, the spraying technique is different, and high-volume parts are better suited to a more industrialised process. The coatings therefore need to evolve accordingly to use across all the application processes,” said Celine Dorignac, segment manager, structures and cabins at AkzoNobel Aerospace Coatings.

“The latest 1K formula represents a potential game-changer for aircraft interior designers and manufacturers who demand more sustainable solutions but without ever compromising on quality.”