Materials science has been undergoing an invisible revolution that offers infinite possibilities to improve material properties and develop new products that solve many of life’s common problems. Nanotechnology has developed at such a pace in the past decades that it has become pervasive, used in everyday applications from clothing to construction, paints to boots, medicine to oil exploration – and aircraft interiors are the next frontier.

We spoke to Dr Lisa Friedersdorf, director of the National Nanotechnolgy Coordination Office (NNCO) of the US government, who has spent decades working in this field. She shared her thoughts on nanotechnolgy advances and the possible applications to solve common cabin interiors challenges, from damage-resistant surfaces to lightweight, power-conserving, in-flight entertainment.

“Nanotechnology really began in the mid-1980s, because we started developing the tools that enabled us to see and manipulate matter on the nanoscale. Since that time, the technique to do this, to imagine and make materials on this scale, and to understand them, has vastly improved,” she explains. “Nanotechnology has really become a part of materials science – all of the engineering and chemistry. It’s a part of what people do. It’s an entirely new toolbox.”

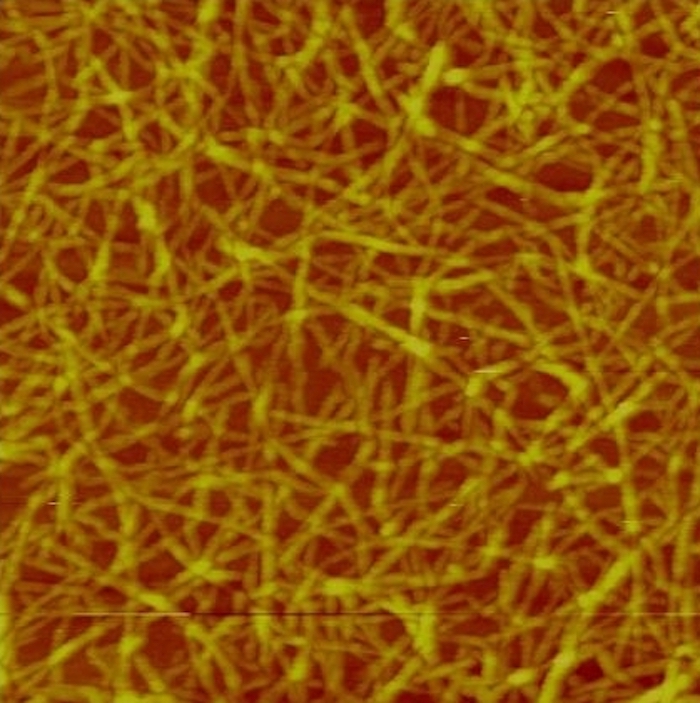

This toolbox involves manipulating matter at a truly minuscule scale. A nanometer is one billionth, or 10-9 of a meter. To put that into perspective, a standard sheet of paper is 100,000 nanometers thick; a single gold atom is about one-third of a nanometer in diameter; DNA is 2.5 nanometers in diameter; a strand of human hair is between 80,000 and 100,000 nanometers wide. Nanotechnology developments such as single-walled carbon nanotubes, which can be used to create a number of useful structures for materials applications, are one nanometer in diameter.

Developing the equipment to see and manipulate materials on this scale was an expensive and delicate process. “While we were developing the understanding in the early phase about how to make these materials, and what properties they would have at this size scale, it was, in the early days, time-intensive and instrument-intensive work,” Friederdorf says. “But in a lot of cases we’ve developed that understanding and there are now mass-market applications of these materials. They’ve become a part of a lot of many everyday things.”

In part, the success of this powerful science is not what grabs consumers’ attention. They may be more aware of the benefits nanotechnology yields, like new stain-resistant fabrics, which mean clothes won’t retain wine stains, and construction workers’ boots that won’t be coated in concrete from the worksite, and kids’ impromptu artwork on the walls at home that is easy to wash off.

Cabin applications

There are existing and developing applications, in both materials and electronics, that might prove attractive to cabin interiors suppliers and designers.

“There are paints that, if you ding or scratch them, can self-heal,” says Friederdorf. “The self-healing paints are polymer matrix with nanoparticles, and the polymer will flow a little to fill in scratches. I know that these are being used in the automotive industry.”

There are different nanotechnolgy applications that would support better cabin hygiene, and improve cabin air quality. “One strategy is antimicrobial, to try to kill the microbes,” says Friederdorf. For example, embedding materials with nanosilver would add antimicrobial properties.

“Another strategy is creating conditions where microbes can’t grow, where it’s not favourable for them to live,” she adds. “Part of that can be a hydrophobic coating, but there are other strategies used as well. With respect to odours, besides killing things that might create odours, like germs, there are also strategies in nanoscale filters. There are materials such as cellulose nanocrystals that have anti-odour properties. There are filters that would use these types of materials. They would work in a similar way to a HEPA filter, but better.”

There are also new developments in water purification using nanotechnology. Nanotechnology can also offer aviation new alternatives for fire-retardant materials that don’t require chemical treatment.

“This is a really important area of research. There are coatings being developed that have nanoclays embedded in them that make them flame-retardant. I’ve seen reports in the automotive industry too, where this is also important. I have colleagues who work with consumer safety, and I’m familiar with the work that they are doing using nano-enabled flame retardants that are more effective and less toxic than some of the chemicals used today,” Friederdorf says.

“I think it’s really important work. I think that looking at areas where nanotechnology can help reduce toxicity or reduce other negative effects is another area. For example, sunscreen is better with nanoparticles and less harmful than the chemicals typically used for this.”

Nano brings in colour

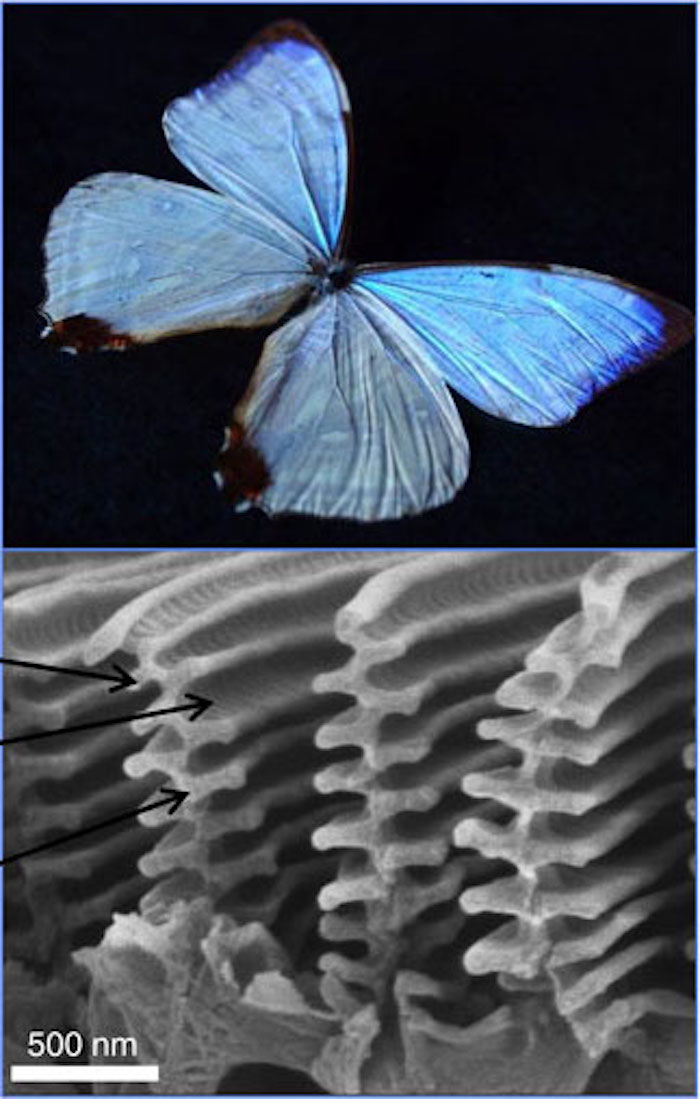

Another interesting possibility in terms of cabin decor is exploring nanopigments, and even nanostructures, which require no pigments but control refraction to create unique polychromatic surfaces that would change colour in response to changes in the light source.

“The Morpho butterfly’s blue colour is not a pigment, it is a structure. That’s an example of a nanostructure creating a color based on the mechanical nanostructure,” she explains. “There are examples of where you can develop structures that will give you a colour, but you have to adjust the wavelength of light based on the structure.”

This same ability to manipulate light can be applied to windows – not just for dimmable displays, but for windows that help better regulate cabin temperature.

“We’re already seeing the use of electrochromic materials for windows, using the application of an electric voltage for infrared and heat blocking instead of window shades. There are concepts that have a thin nano-crystalline layer. Potential changes to the structure of that layer would make it transparent or opaque,” Friederdorf says. “Nanostructures give you flexibility in letting through different wavelengths of light. In winter, you might want rays that give you heat as well as light, and in the summer you might want the light without the heat. The technology is advanced enough that you could buy it, but it’s probably not something that we could all afford in our homes.”

Nano makes cabins clever

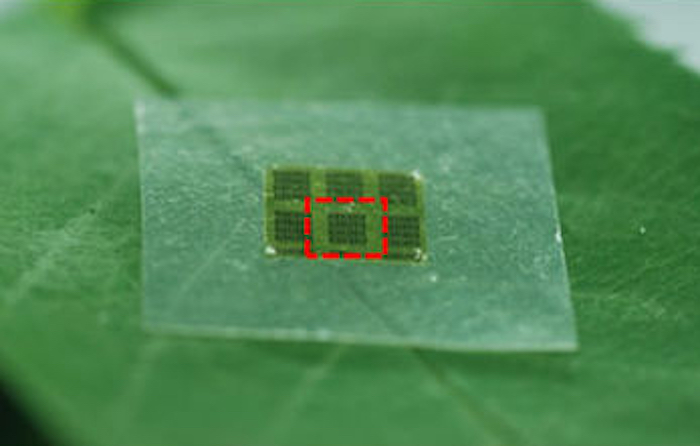

Nanotechnology could also make cabin interiors smart, by being applied in embedded biometric sensors. Biometric sensors are already being embedded into the fabrics of high-end athletic clothing, and Friederdorf believes they might be used to fight the negative effects of sitting or lying in aircraft seats over a prolonged period.

“I can envision a seat that has embedded sensors that can change seat settings on a finer scale. The sensors could detect temperature or your comfort level by whatever measure you want to measure,” she says. “I can see there being sensors embedded in the seat that might enable you to reinvent comfort. Maybe there’s a way to adjust the seat so that it’s more comfortable for the individual. You could imagine having some sort of actuator that could essentially blow the cushion up a little bit more, to change the level of comfort.”

Nano armour

Tomorrow’s aerospace nanomaterials might also be organic and biodegradable. “One of my favourite materials is cellulosic nano-materials,” Friederdorf says. “They can be made out of waste wood, or different plant materials. What’s interesting is that they have a very high strength, but are lightweight. They are similar to what you hear about with carbon nanotube-based composites, but are nanocellulose. They also have interesting optical properties. They are doing things like looking at high-strength and transparent armour, for lightweight bulletproof windows. They are being explored for a number of applications.”

“We’re using a 70-year-old nucleation theory to solve a 100-year-old problem with a 21st century machine,” explains Hunter Martin, a scientist who co-led the research team.

The process of additive manufacturing with metals typically begins with alloy powders that are applied in thin layers and heated with a laser or other direct heat source to melt and solidify the layers. However, if high-strength unweldable aluminium alloys such as Al7075 or AL6061 are used, the resulting parts suffer severe hot cracking, rendering them useless.

The HRL team has developed a nanoparticle functionalisation technique that it claims solves this problem by decorating high-strength unweldable alloy powders with zirconium-based nanoparticles.

The nanoparticle-functionalised powder is fed into a 3D printer, which layers the powder and laser fuses each layer to construct a three-dimensional object. During melting and solidification, the nanoparticles act as ‘nucleation sites’ for the desired alloy microstructure, preventing hot cracking and allowing for retention of full alloy strength in the manufactured part.

According to the team, its nanoparticle functionalisation techniques can also be used to make previously unweldable alloys weldable. Even better, it says the technique is scalable and uses low-cost materials.

“We designed this vehicle to use the nanocomposite parts because they are lightweight, and they don’t change shape when subjected to temperature changes,” stated Bill Knapp, programme engineering manager for the H2.

The H2 wasn’t GM’s first application of nanocomposites: it introduced them on the step assist of the 2002 GMC Safari and Chevrolet Astro vans. In 2004, GM expanded its use of nanocomposites, using them on body moldings for the Chevrolet Impala. In 2004 GM was the biggest user of olefin-based nanocomposite material in the world, using about 660,000 lb (299,370kg) per year.

“The virtue of using a nanocomposite is that less filler material is required to provide the same or better performance characteristics when compared to conventional materials,” said Will Rodgers, staff scientist, GM R&D. GM uses nanotechnology throughout its vehicles today, including in stain-repelling textile treatments.