Imagine that you have in front of you a piece of paper.

If you fold it in half, you reduce its original size by 50%. Fold it in half again, and you reduce it by another 50%. However, when you get to the eighth fold and try to fold it in half, it is no longer possible – and so to reduce the surface area further, the entire process needs to change.

Out goes the folding, in come the scissors.

This is a neat way of introducing the concept of process change, although as is usually the case, if you leave enough scientists in a room for long enough, they will confuse the issue. For example, some scientists now postulate that, given a piece of paper large enough, and enough energy for folding, it can be folded as many times as you like. Problem is, when you get to the 103rd fold, the thickness of the paper will be larger than the observable universe, i.e. 93 billion light years!

For the purpose of this article, therefore, we will stick with the eight-fold rule. And at the eighth fold the process must change.

Challenges in micro manufacturing

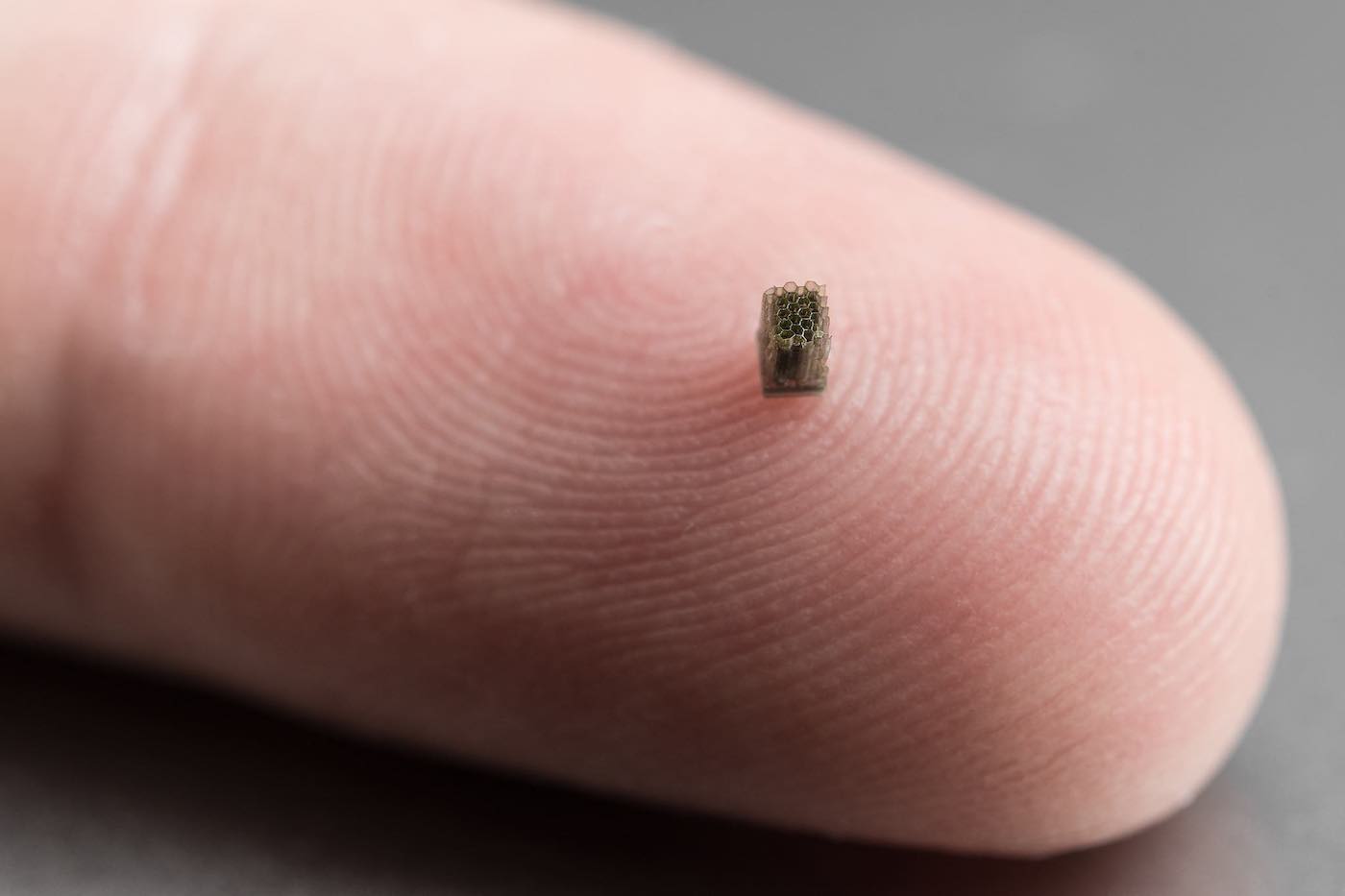

Miniaturisation is the driving force behind the Nanofabrica company, and is something that nearly all key industry sectors strive for in new product development, be it for weight savings, promoting minimally invasive diagnostic or treatment devices in medical scenarios, or a range of advantages that revolve around smaller footprint and increased functionality.

But making things smaller, while seemingly a simple concept, is in fact extremely difficult, and is the obsession of R&D departments working in this space. Scaling down is fine, but at some point, products and components become so small that they are incompatible with the material or fabrication process being used.

Many companies attempting to manufacture at smaller and smaller scales are confronted with problems. Not only is the practice of micro-manufacturing itself complicated, but manufacturers are often forced to use technologies to manufacture at the micro-scale that are in fact scaled-down versions of macro technologies, and these are often over-engineered and large-footprint technologies that are not an efficient solution in micro manufacturing scenarios.

Indeed, in some areas like plastic moulding for example, machines that are designed to facilitate micro-moulding are often not fit for purpose, or are so expensive to buy and to run that they considerably ramp up the cost of manufacture at the micro scale.

Couple this with the fact that these scaled-down macro-moulding machines suffer from the side effects of residence time and material degradation common to all moulding processes, (but exacerbated at the micro scale), and use clamping forces and moulding pressures way in excess of what is necessary for micro moulding, and the demand for alternative technology solutions is obvious.

For reasons based on both physics and practicality, techniques used in macro-scale moulding, machining and indeed assembly are inappropriate for complex devices with micron-scale features.

Assembly is an interesting issue when looking at the micro-scale manufacturing. The laws of physics mean that there is a particular set of problems when attempting to assemble small items.

As you move from a macro-scale part to a micro-scale part, when all dimensions scale equally, if one dimension decreases by a factor of 10, volume decreases by 1,000. Because of this, the force from gravity (which is related to mass) is also reduced by 1,000. However, the force from friction with surrounding objects will only decrease by a factor of 100 because it is dependent on area. As objects get smaller, therefore, surface forces such as friction begin to matter much more than gravity does.

For an assembly operation this has major implications, and again, the demand for a process change that decreases or eliminates the need for assembly is huge.

The need for process change in micro manufacturing

Working at the micron level in fabrication, additive manufacturing (AM) technology is key to the optimisation of processes and materials to create ever-more precise and smaller parts and components. Nanofabrica’s AM technology has for the first time given OEMs working to manufacture small-scale micro plastic parts an opportunity to change the process.

In this way, Nanofabrica exists at the eighth fold, and provides an alternative technology that allows manufacturers to overcome the restrictions of conventional micro-manufacturing technologies.

AM has existed as a technology for nearly three decades, but has only really become a true alternative “production” technology in the last few years, its previous value being in the area of rapid prototyping.

It is in the area of production that AM is truly disruptive, and is causing manufacturers to assess the value of changing their manufacturing processes to achieve the cost-effective manufacture of innovative and cutting-edge products and components.

Nanofabrica has focussed its resources into the development of a commercially viable mass-production AM platform specifically for micro-manufacturing applications, and as such has pioneered a technology that facilitates process change in the micro-manufacturing arena.

For the first time, micro manufacturers can now realistically assess a shift to AM from conventional manufacturing processes as they get to the eighth fold. OEMs can therefore benefit from the inherent advantages that AM offers in terms of promoting part complexity with no increase in cost, eliminating the need for expensive tooling, reducing part counts and the need for assembly, speeding product development times, enabling easy revision of part designs, mass customisation, reducing waste, and reducing energy costs.

Nanofabrica’s AM technology combines innovation in materials, software and hardware to allow the repeatable mass manufacture of micro parts and components with micron-scale features. Today it is the eighth-fold alternative for manufacturers in the areas of micro optics, semiconductors, micro electronics, MEMS, micro fluidics and life sciences, making products such as casing for microelectronics, micro springs, micro actuators and micro sensors, and numerous medical components such as micro valves, micro syringes, and micro implantable or surgical devices.