Lightweight and high-strength materials have become indispensable for high-end applications in the aviation industry. In passenger aircraft every kilogram counts, which is why metals are increasingly being replaced with plastics-based solutions, including the interior designs. Thermoplastic composites, in particular, offer companies kitting out aeroplanes significant weight reduction without requiring them to make compromises in terms of mechanical properties. A project by two aerospace companies – Bucher Leichtbau and Ensinger – has shown that making the switch to fiber-reinforced composites can provide additional technical advantages.

Bucher Leichtbau is a specialist in aircraft interiors and automotive equipment, with expertise including developing and producing galleys and cabinets for passenger aircraft. A full module of this type can accommodate a load corresponding to eight times its own weight and has to be able to withstand accelerations that are at least nine times that of gravitational acceleration. Here, a distinction is drawn between flight loads (normal flight conditions such as take-off, landing, turbulence) and emergency landing loads (controlled emergency landing or aborted take-off). The required minimum operating life of the modules produced can be 25 years for Airbus and Boeing, for example.

Initial situation: material and installation costs

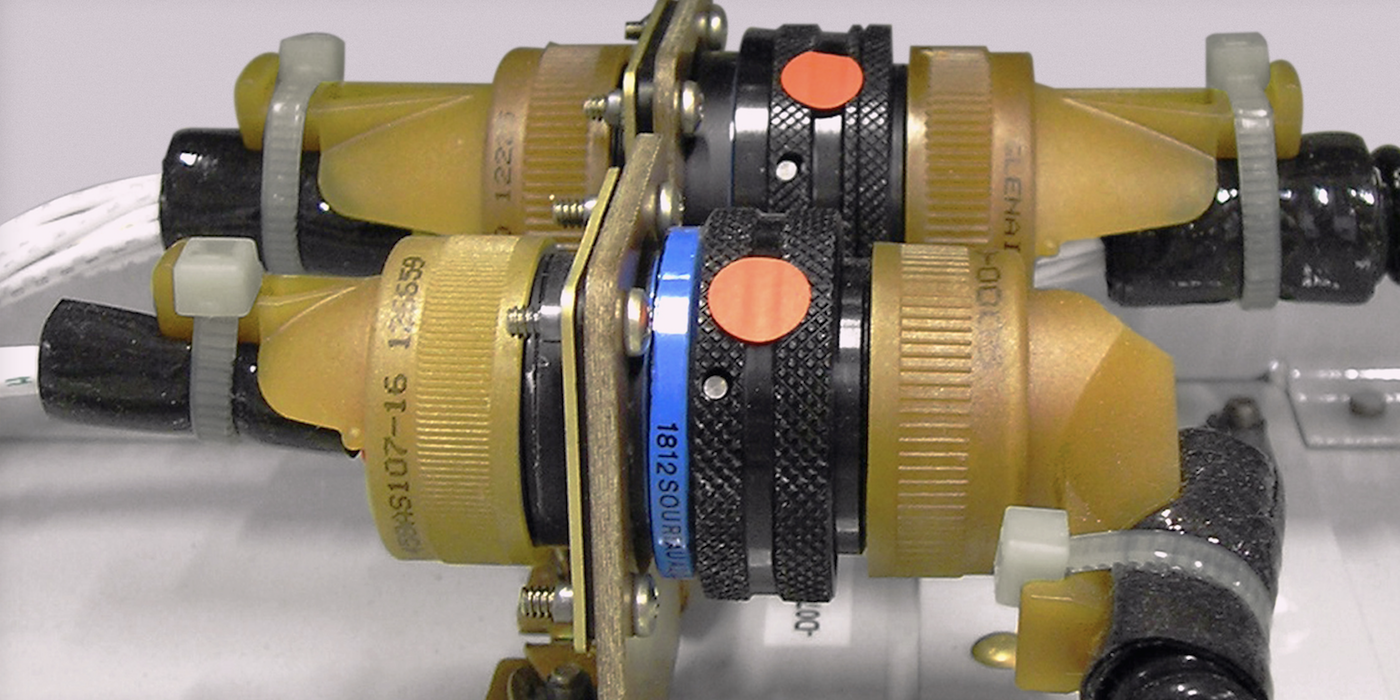

For safety reasons, all metal mountings for electrical plug-in connections in commercial aviation must be earthed. With electrically conductive, supporting structures in aluminum galleys, an existing fastening screw equipped with the necessary corrosion protection measures is often sufficient.

If, however, the metal connector mountings are positioned on non-conductive structures in a galley, an additional cable is required for the electrical earthing. This earthing cable must be secured at regular intervals, which drives a requirement for additional fastening threads, spacer bolts, cable clamps and screws.

In addition to the material input for the cable routing, high costs arise for planning and installation. The design work includes making an entry in the schematic circuit diagram; what is more, a resistance measurement must be defined in the test plan for every earthing cable. This must also be incorporated into the relevant maintenance guidelines and operating instructions, as well as into the authorization documents. During production, the contact resistance must be recorded and a corrosion protection coating be applied with every earth connection.

Metal substitute removes the need for earthing

The work and costs involved in an earth connection can be completely eliminated if the connector mountings previously made from metal are replaced by a non-conductive variant. Because of the operating temperature and fire safety requirements, however, it is not possible to use a low-cost, standard plastic.

For Bucher, the sought-after technical alternative needed to be capable of replacing a large number of existing sheet aluminium parts one-to-one so as to minimise the work and costs involved in switching when they were introduced. For this demand to be met, a rigid, high-strength material is required.

Owing to the relatively small quantities of the different connector mountings, a solution with high tool costs was not an option. Initial trials with locally remodelled parts made from fiber-reinforced thermoplastic sheet material did not show satisfactory results in the remodeled zones.

Thermoplastic composite components

The breakthrough was achieved during their first cooperative venture with Ensinger GmbH. On the basis of Bucher’s requirement specifications, Otelfingen’s composites division in Otelfingen, Switzerland developed a solution on the basis of thermoplastic fiber-reinforced composite. A pre-preg approved for the aviation industry with glass fiber and a PEI matrix (polyether amide) was chosen for the material. After a brief optimization phase, it was possible to manufacture the first series-produced parts. Because of the specialist processing techniques, two of the Ensinger’s sites are involved in the production of the connector mountings.

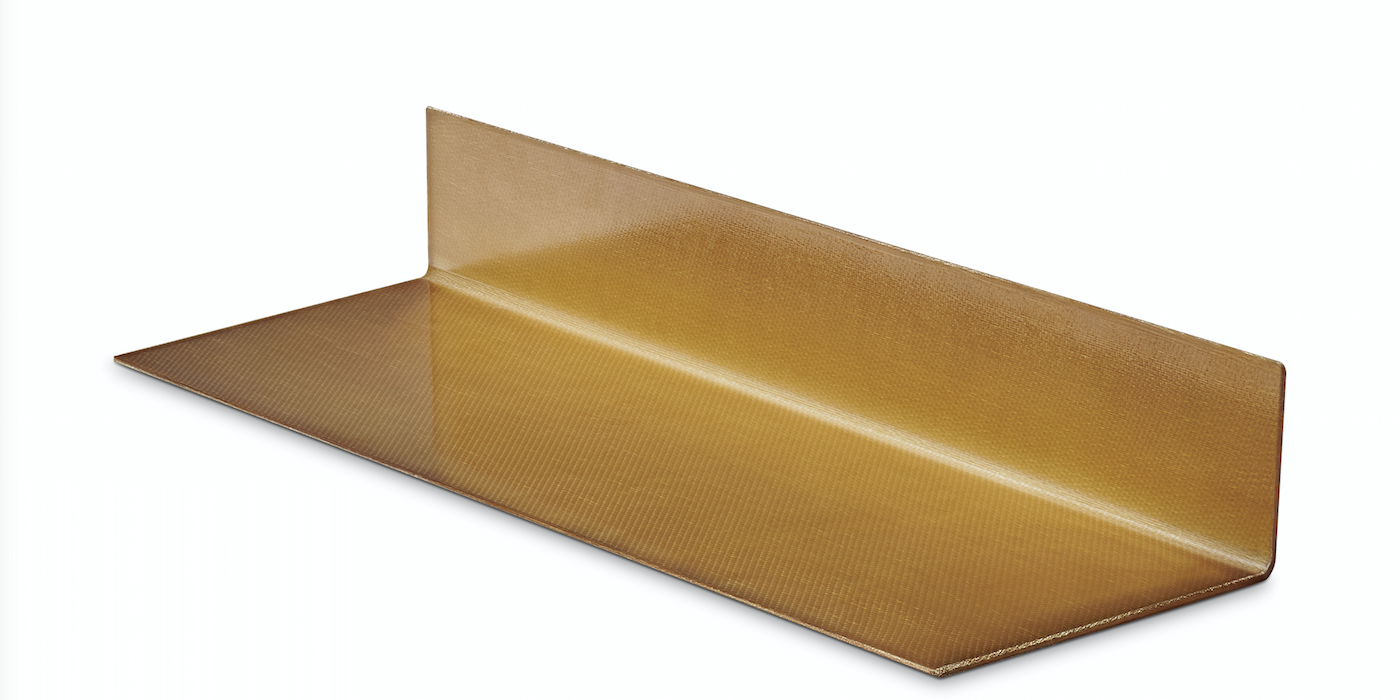

At the Otelfingen site, Ensinger’s composite experts produce semi-finished parts in an angular shape from the PEI pre-pregs. Unlike comparable components, these blanks are not cut to size from a thick laminate and thermoformed but, using individual pre-preg layers, pressed in a tool into the defined form. Among other things, this process offers the advantage of reducing the springback effect.

The CNC processing of the fiber composite parts takes place at Ensinger’s subsidiary, Trig Engineering, in the UK, which specializes in the production of precision parts from thermoplastic high-performance plastics and composite materials. From the angular blanks produced in Otelfingen, the company precision-machined the connector mountings to final product specification.

For most fastening brackets there are several versions with different dimensions. Thanks to the flexible process, it is also possible to produce high-quality, special designs with contours or drilled holes and with short lead times.

Simpler, more cost-effective, and lighter

The manufacturing costs for the new plastic mountings are significantly higher than the previous version in aluminum. However, the savings in terms of engineering and production of the cabinets means that the new solution is still considerably more straightforward and, importantly, more cost-effective overall. As the galleys are lighter thanks to the use of composite components, the airlines benefit in the long term because every kilogram of additional weight which does not have to be taken into the air saves money.

Thanks to the preform technology, differences in wall thicknesses are also possible when producing angles. So in a similar way to with a forked branch, the corner section under high strain can be reinforced, while in the sections which are not under as high strain (e.g. on the arms), material can be conserved. The manufacturing technique is referred to as the ‘near net shape’ process. Depending on the component geometry, significant material and weight savings are possible with this technology – whilst maintaining comparable strength and rigidity.